4

4.0 Installation

(continued from page 2)

Leave Room For Adjustment

Immerso-Pak burners can be purchased with three different valve train packages. All

three packaging options integrate an adjustable bias proportionator. Thus, allow a

minimum of 6" (152 mm) of space beneath the proportionator stem for bias adjust-

ment, as shown in Figure 3.

Gas Metering Orifice

Each burner is test fired at Eclipse before shipment and supplied with a tag (Figure 6)

showing the differential gas pressure that corresponds to maximum rated input. This

provides only an approximate measurement of gas flow. For more precise measure-

ment, or if the burner will be operated at less than maximum input, install a gas meter-

ing orifice upstream of the burner.

When using a gas metering orifice, provide a straight run at least ten pipe diameters

upstream and at least five diameters downstream of the orifice. Failure to comply will

cause inaccurate meter readings.

Piping Suggestions

Strictly follow the system designer’s recommendations on pipe sizing and layout. If you

insert piping elbows not planned for in the original design, you may introduce exces-

sive pressure losses which can prevent the system from performing properly.

Use flexible nipples on burner air and gas inlets. Solid piping may restrain the burner

from thermal expansion and damage the burner or its piping components.

Do not use the burner assembly to support the piping.

Gas piping must comply with American National Standard “National Fuel Gas Code”

(NFPA No. 54 or ANSI Z223.1)*, or must be acceptable to the authority having jurisdic-

tion.

General Wiring Suggestions

See Figure 4 for wiring diagrams.

Electrical wiring must comply with the National Electric Code*, (NFPA Std. 70 or ANSI-

CI 1981), or must be acceptable to the authority having jurisdiction.

*Available from:

National Fire Protection Association

American National Standard Institute

Batterymarch Park

1430 Broadway

Quincy, MA 02269

New York, NY 10018

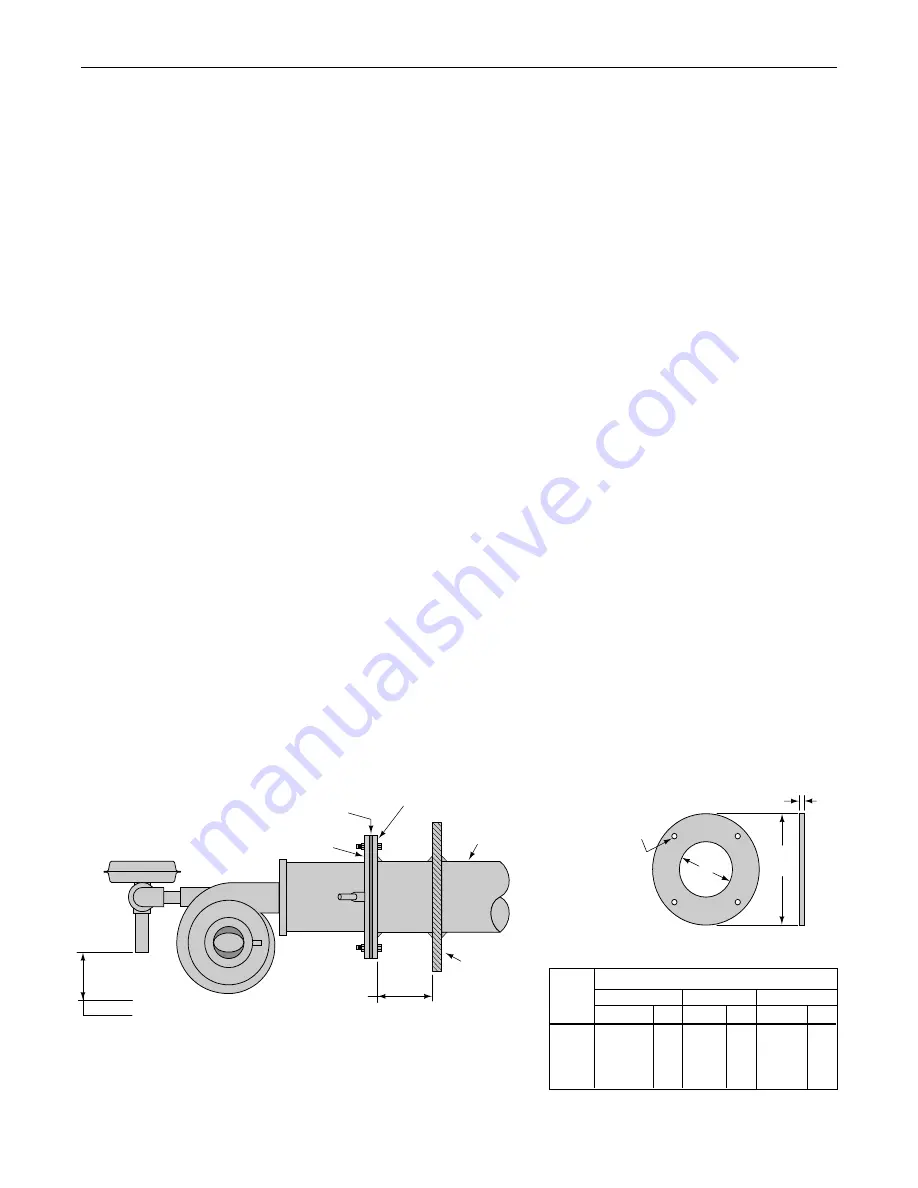

Figure 3 – Burner Mounting

Allow 6" (152 mm) Of Space

Beneath Proportionator Stem

For Bias Adjustment

Tank Wall

Immersion

Tube

Companion Flange

(By Customer)

Gasket

6"

(152 mm)

Maximum

Burner

Mounting Flange

Four

Mounting Holes

7/16" (11mm) Dia.

On “C” B.C.

1/4"

(6 mm)

“B”

Dia.

“A”

Dia.

Dimensions

A

B

C

Burner

Inches

mm Inches mm Inches mm

124

6-11/16 170 11-7/8 302 10-11/16 271

132

8-11/16 221 11-7/8 302 10-11/16 271

140

10-13/16 275 14-7/8 378

14

356

148

12-13/16 325 14-7/8 378

14

356

Companion Flange Dimensions