EBS Ink Jet Systeme GmbH

D-51588 Nümbrecht, Germany, Alte Ziegelei 19-25

++49 (0)2293/939-0

++49 (0)2293/939-3

e-mail: [email protected]

20

20140417#2.2

edited on 2014.04.17

18

the iModule

®

replacement procedure starts and it can take up to 20 minutes. The following message is dis-

played:

iModule replacement procedure

in progress.

iModule is under pressure !!

Do not remove iModule.

Wait for relevant message.

At that time the flow of ink in the head is stopped, the ink filtering procedure takes place for a short time and ink

system pressure is reduced (these operations are indicated by the blinking green LED above the

INK

ON

/

OFF

key on

the operation panel). Wait for the following message:

While the printer is running:

- Press transport protection,

- Remove iModule & wait

for next message.

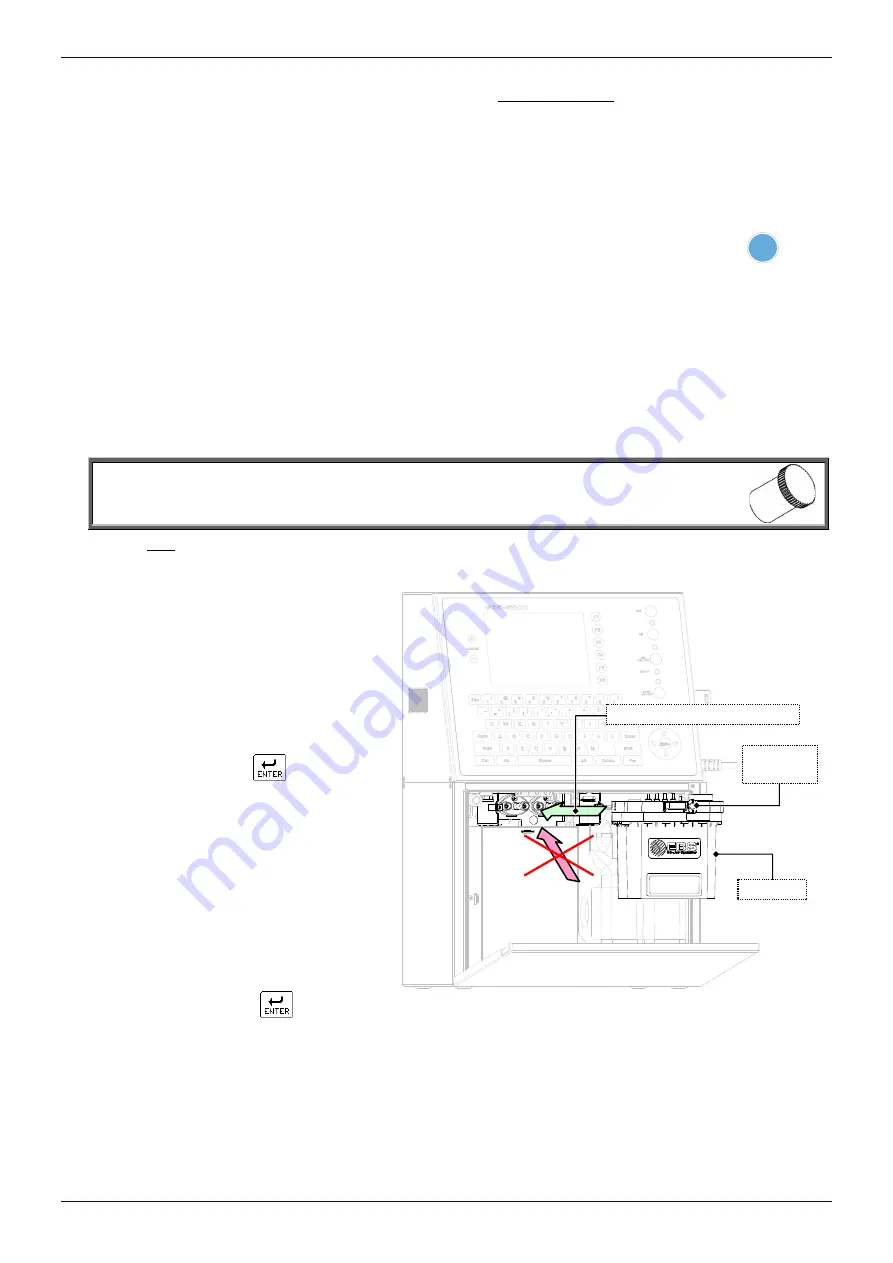

5.

Close the transport-safety valve (see

) and then remove iModule

®

from the printer. In order to pull out

the iModule

®

from the inside of the ink system chamber you need to tilt two fastening latches aside (see

). A few seconds after this operation the following message is displayed:

Insert iModule & wait

for next message.

NOTE:

The connections of the iModule

®

removed should be secured against potential leaks with spe-

cial plugs supplied together with a new Module

®

.

6.

Install a new iModule

®

in the printer by pushing the module along the slideways to the limit (when the iModule

®

reaches its proper position, the latches make a characteristic sound – a ”click”). When the module is detected

in the printer, the following message is displayed:

A new iModule detected

Operating time

hhhh:mm

Expiry date

dd.mm.yy

Shelf

life

dd.mm.yy

C=0

Do you really want to install it?

(Y,N)?

and the

BOTTOM

LED on the inner

panel starts blinking, which means that

the module is empty.

7.

After the ”

Y

” key or the

icon has been

pressed as confirmation, the following mes-

sage is displayed:

CODE VERIFYING:

WAIT 10 SECONDS PLEASE

and in a few seconds - another one:

Open transport protection,

and then press ENTER.

Follow the above given request (and that on

the

sticker on the

iModule

®

) and

open

the transport-safety valve of the iModule

®

(see

). When the operation is com-

pleted, confirm it with the

transport

valve

iModule

®

iModule

®

installing direction

Fig. 5.2.1