11

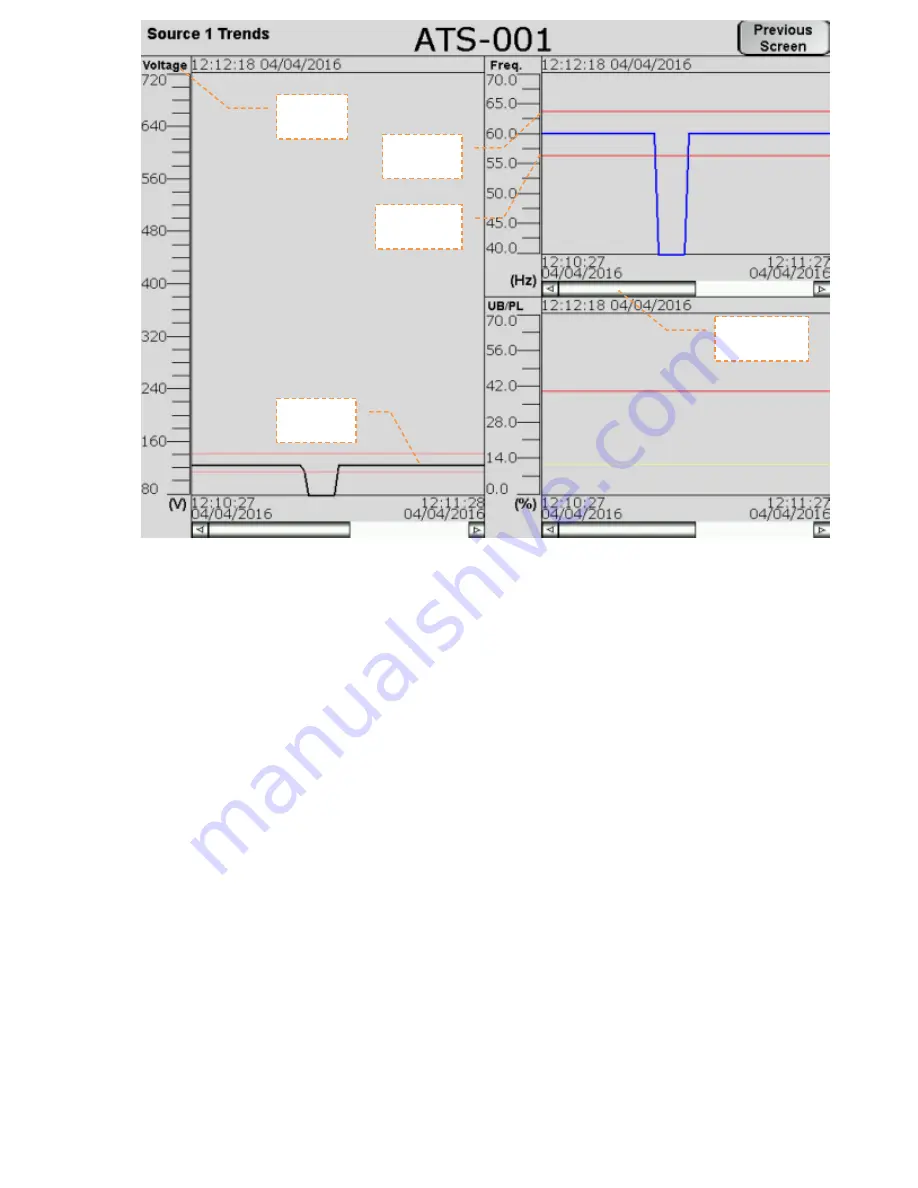

The Trend screens show a graphical representation of Voltage, Frequency,

Unbalance, and Amperage (Load trend only). The HMI takes data samples every 1

second for each controller it communicates to. The internal storage of the HMI can

store up to 5.25 days of historical data on the single-view firmware, and up to 8.9

hours of historical data on the multi-view firmware. The HMI can be configured from

the factory to export and store this data on an external USB drive or SD card.

Additionally, data saved to external devices can be viewed on any PC program that

supports CSV files.

If applicable, the trend windows also display the Under/Over-Frequency, Voltage, and

Unbalance limits as set in the ATC-900. These are depicted by the red horizontal lines

on each trend window.

To view trend data on the HMI, simply press the Trend button of the voltage source

you wish to view (Source 1, Source 2, or Load). Once on the trend screen, you can go

back and forth through time by using the scroll bar and arrows on the bottom of each

trend window. The most recent data is on the

right

side of the window, while the oldest

data is on the

left

side. To see a data point value at a specific point in time, press on

the screen at the desired point and the HMI will draw a vertical line there and display

the data value.

Navigation

Sliders

Trend

Label

Current

Data Pen

Overfreq.

Range

Underfreq.

Range

Summary of Contents for HMIVU07CUNBE

Page 9: ...9 ...