I.L. 17403

Page 14

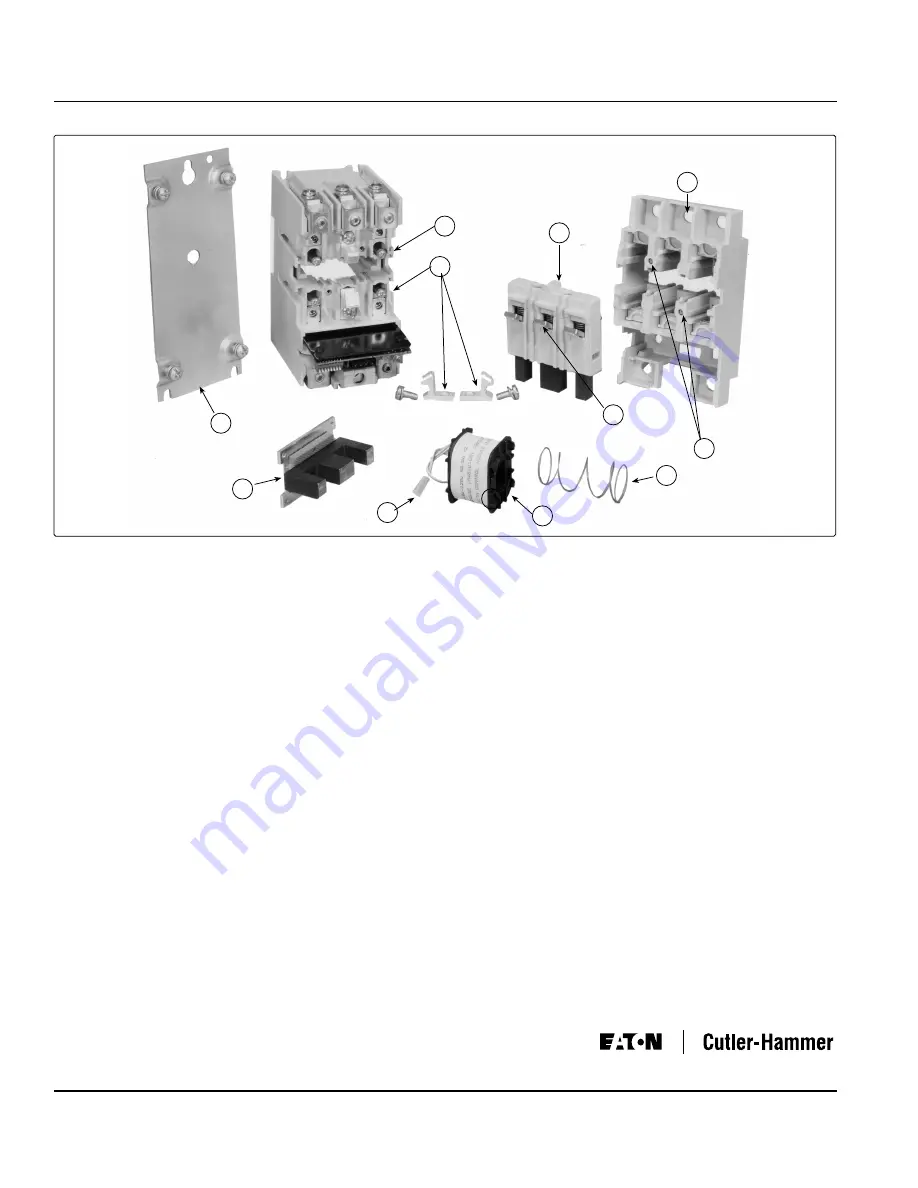

Fig. 14 Size 3 W200 Starter (Exploded View)

4201 North 27th Street

Milwaukee, WI 53216

Effective 9/04

Printed in U.S.A.

J

K

A

L

C

B

D

H

F

E

A

G

To Replace the Coil

Refer to Figure 14. Loosen the two captive arc box assembly

screws, Item G. Remove the arc box cover, Item H and

the crossbar assembly, Item B. Remove the four stationary

contacts, Item C, from the outer poles. Remove the base-

plate, Item J. Note the molded connector, Item E, containing

the two coil leads attached to a plug on the circuit board.

With a small screwdriver, lift the latch that holds this con-

nector and slide it off the plug. Loosen the four screws,

Item F, that are accessible via the deep holes under the

stationary contacts and free the plate, Item K, that holds

the E-shaped magnet. Do

not

remove the magnet from

its supporting plate, Item K. Remove the old coil, Item A.

Reassemble with the new coil positioned so that the long

projections on the coil bobbin engage the magnet and coil

leads are down. Position the return spring, Item L, between

the circular recess in the underside of the arc box and the

circular recess in the top of the coil bobbin. Attach the coil

lead connector, Item E, to its plug. Tighten the four screws

that hold the magnet supporting plate to 12-18 lb-in. Re-

place the stationary contacts, crossbar assembly, and arc

box cover, Item H. Tighten the arc box cover screws to 12-

18 lb-in.

Magnet Armature Assembly

Self-alignment and permanent air gap features of the mag-

net make replacement unnecessary. Mating pole face sur-

faces should be kept clean.

MAINTENANCE - TURN OFF POWER!

This industrial type control is designed to be installed, op-

erated, and maintained by adequately trained workmen.

These instructions to not cover all details, variations, or

combinations of the equipment, its storage, delivery, in-

stallation, checkout, safe operation, or maintenance. Care

must be exercised to comply with local, state, and national

regulations, as well as safety practices, for this class of

equipment.

To Inspect Contacts

Refer to Figure 14. Loosen the two captive arc box cover

screws accessible through holes in the nameplate and

remove the arc box cover, Item H. Remove the crossbar

assembly, Item B, containing the movable contacts. Station-

ary contacts, Item C, and movable contacts, Item D, are

visible. The silver cadmium oxide contacts need

NO

dressing or lubricant throughout their life.

Important -

Replace all contacts and springs as a group

to avoid misalignment.

To Replace Contacts

With the cross bar assembly removed, remove the two

stationary contacts, Item C, per pole. Discard all old parts,

including the magnet armature attached to the old crossbar.

Reverse the procedure to reassemble, tightening the new

stationary contact screws that hold the new stationary

contacts in place to a torque of 48-72 lb-in. Replace the

crossbar assembly, Item B, and arc box cover. Tighten

the arc box cover screws to 12-18 lb-in.