GFSX1 ground fault circuit interrupter

Installation & maintenance information

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

IF 1937

IMPORTANT INFORMATION

A GFSX1 ground fault circuit interrupter reduces the hazards of ground fault currents that

can cause loss of life. Upon detecting a ground fault current (exceeding 5 milliamps) in the

protected branch circuit, the GFSX1 unit will trip, interrupting power. Even with GFSX1 unit

limiting ground fault current, some electrical shock may be felt. Such shock will normally

be of less than dangerous duration. However, persons with heart problems or other

medical conditions that may make that person susceptible to the effects of electrical shock

may still be seriously injured. While the GFSX1 ground fault circuit interrupter provides

a significant level of protection, there is no known device that can provide complete

protection from all hazards of electrical accidents under all conditions.

The GFSX1 unit will not protect against short circuits or overloads. A circuit breaker or fuse

controlled switching system that supplies power to the branch circuit must provide that

protection.

When the GFSX1 unit has interrupted a ground fault current caused by faulty insulation,

defective equipment or wet wiring, the fault must be repaired before the GFSX1 unit is

reset. The GFSX1 unit must be tested upon completion of initial installation and at regular

intervals in an established testing program.

APPLICATION

GFSX1 ground fault circuit interrupter is used with portable electrical equipment to protect

against possible injury due to unwanted ground faults, meeting the requirements for

personnel protection as defined by the National Electrical Code (NEC), Canadian Electrical

Code (CEC) and the Canadian Standards Association (CSA). When mounted on proper

body, no additional sealing is required. A factory sealed chamber encloses the unit in a

housing with explosionproof ground joints.

GFSX1 interrupter is suitable for use in Class I, Division 2, Groups B, C, D; Class II, Groups

E, F, G; Class III hazardous locations.

NOTE:

When used on EDS multi-gang boxes

combined with an ENRX receptacle, they are only suitable for Class I, Division 2, Groups

B, C, D; Class II, Groups F, G; Class III hazardous locations. ENRX receptacles are not

suitable for use in Class II, Group E environments, including when used as ENRX GFCI kit

(example: ENRX22201 GFI).

GFSX1 ground fault interrupter is a feed though type to serve receptacles in a branch

circuit of 15 to 20 amperes at 120 volts AC. They are intended for use with Crouse-Hinds

series ENRX receptacles.

IF 1937 • 11/22

Copyright © 2022, Eaton’s Crouse-Hinds Division

Page 1

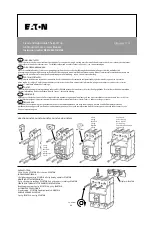

INSTALLATION

Before starting, read all instructions contained in this installation and maintenance

information sheet.

1.

Install single-gang or two-gang standard, or two-gang or three-gang tandem EDS or

EDSC device box (ordered separately) in desired location and connect into grounded

conduit system.

NOTE:

GFSX1 units cannot be installed on EDSCM multi-gang modular control device

bodies.

2.

Pull all power source (line) wiring and receptacle (load) wiring into device box.

3.

Attach wiring from GFSX1 factory sealed chamber to power source and receptacles

wiring in an approved manner. Make all connections following wiring diagram for your

specific wiring system.

4.

Insert wiring, then factory sealed chamber into device box with internal TEST and

RESET buttons positioned correctly. TEST button on external cover MUST be lined up

with TEST button of device in sealing well (clearly marked).

5.

Place external cover over factory sealed chamber per Step 4, and attach with the four

(4) screws provided. Tighten screws to 60 in.-lbs. torque.

6.

Do not use GFSX1 unit until it has been fully and successfully tested as specified in

TESTING PROCEDURE.

!

CAUTION

To avoid the risk of electric shock:

•

Installation and maintenance procedures must be performed by a trained and

competent electrician.

•

Be sure all electrical power is OFF before starting installation and maintenance.

•

Install on 120 VAC grounded circuit only that is protected by properly rated

circuit breaker or fuse.

•

Install GFSX1 between circuit breaker or fuse and receptacles.

•

Connect to copper wire only.

•

Install GFSX1 unit as close as practical to protected receptacles.

!

WARNING

To avoid the risk of explosion and to maintain environmental rating:

Clean both ground joint surfaces of cover, internal sealing chamber and device

box before tightening screws. Dirt or foreign material must not accumulate on flat

ground joint surfaces. Surfaces must fully seat against each other to form a proper

explosionproof seal.

TESTING PROCEDURE

1.

Turn power ON to branch circuit receptacle protected by GFSX1 unit.

2.

Press the TEST button on GFSX1 unit, the RESET button should extend outward.

3.

Plug a test lamp or meter into a protected receptacle. If the test lamp lights (or

meter indicates a voltage reading), this indicates that the connections have been

wired incorrectly. Turn off power to circuit and correct wiring before proceeding

further. If the test lamp does not go on, or meter indicates zero voltage reading,

proceed to the next step.

4.

Press the RESET button firmly until an audible click is heard. The test lamp should

now turn on. Press the TEST button again. The test lamp should go OFF and RESET

button extend outward. This indicates proper wiring connection to that receptacle.

5.

With the RESET button extended, test the other receptacles in the branch circuit

protected by the GFSX1 unit. If the test lamp lights or the meter indicates a voltage

reading, this indicates that the receptacle is NOT protected by the GFSX1 unit. Turn

power OFF to circuit and correct the wiring. Test all receptacles protected by the

GFSX1 unit.

6.

Attach the self-adhesive “GROUND FAULT PROTECTED” label to each receptacle

protected by the GFSX1 unit.

7.

Establish and maintain a regular monthly testing schedule.

!

WARNING

To avoid the risk of explosion and to maintain environmental rating:

If receptacle to be tested is located in a normally hazardous area, that area must be

purged of the hazard and declared non-hazardous before starting testing procedure.

!

WARNING

To avoid risk of electric shock and to maintain environmental rating:

Keep cover screws tight when in operation. Only use screws supplied with the

assembly or Eaton’s Crouse-Hinds replacement screws.

MAINTENANCE

1.

Perform visual, electrical and mechanical inspections on a regular basis. The environ-

ment and frequency of use should determine this. However, it is recommended that

checks be made at least once a year.

2.

Make sure screws holding the GFSX1 cover and sealing chamber to the back box are

tight. Inspect flange gaskets for damage. Ensure gaskets are fully seated in the gasket

groves.

3.

Inspect machined flanges for any damage or corrosion.

In addition to these required maintenance procedures, we recommend an Electrical Preventive

Maintenance Program as described in the National Fire Protection Association Bulletin NFPA

70B: Recommended Practice for Electrical Equipment Maintenance (www.nfpa.org).

WARNING

To avoid risk of explosion,

If any part of the ground fault circuit interrupter appears to be broken or shows signs

of any damage - discontinue use immediately. Replace the item before continuing

service.

Replace devices if the machined flange is damaged, scratched, dented or corroded.

Field re-work of machined flange is not possible.

!

!

CAUTION

To avoid risk of explosion:

Mount GFSX1 ground fault circuit interrupter to Eaton’s Crouse-Hinds series EDS

back boxes.