EATON

WSB11206 WCSB Tensioner / Brake with ORB Coolant Ports Installation, Operation and Maintenance Manual E-CLCL-II009-E

August 2015

24

WCSB tensioner / brake with ORB coolant ports

4.5.5.4 Applying the Gasket Tape to the IRON.

(a)

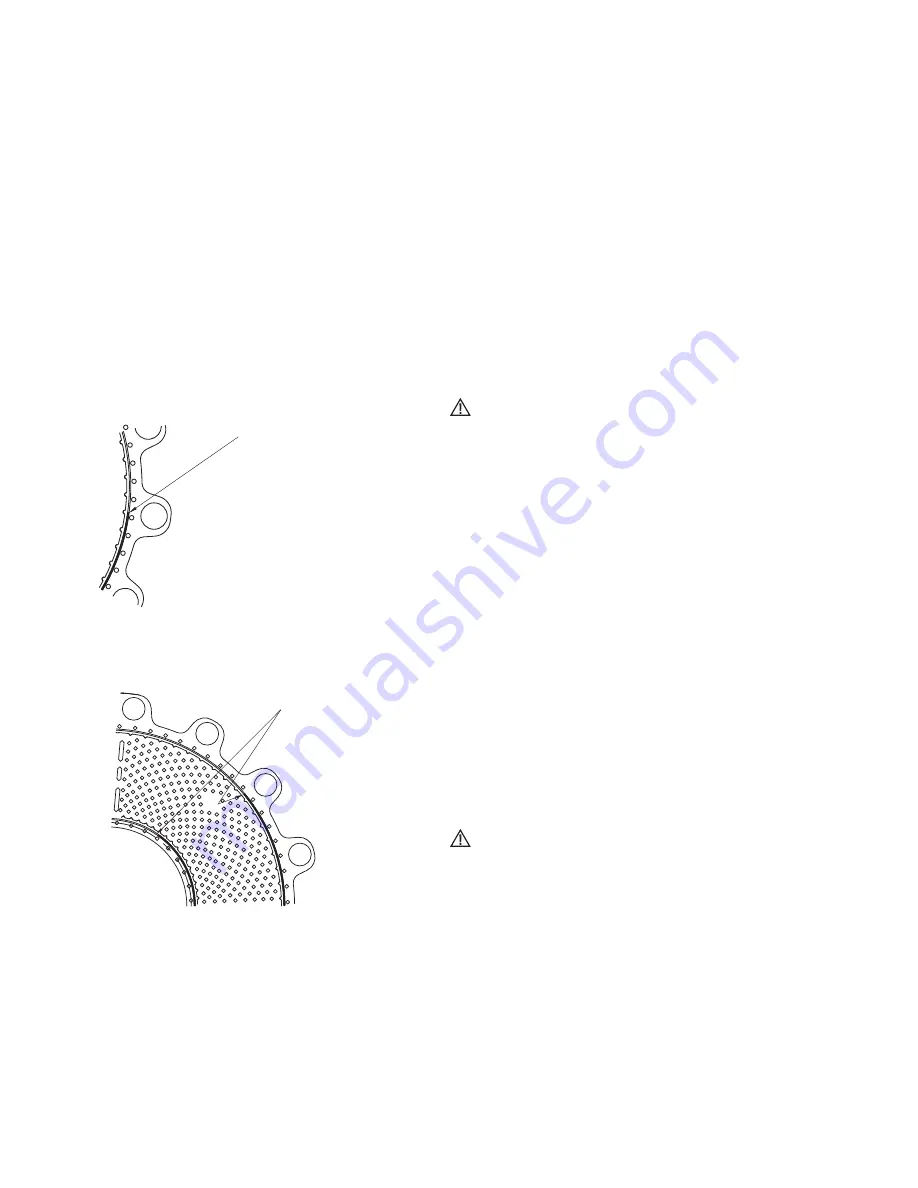

Start with the sealing area nearest to the inner

diameter on the IRON. Remove the adhesive backing

on the gasket tape a little at a time to prevent the

adhesive from picking up dirt during installation.

Start by positioning one end of the tape at the

center-line of a bolt hole as shown in Figure 10, using

the edge of the water cavity as a guide as shown in

Figure 11. Proceed to apply the tape on the sealing

surface following a smooth circular path, being sure

to press the tape in place.

Note: The tape will cover the machined groove that is located

between the water cavity and the bolt holes.

Start location of Gasket Tape

Gasket tape starts at

centerline of bolt hole

(Tape for inner and outer)

Figure 10

Placement of Gasket Tape

Gasket tape placed

using edge of water

cavity as guide and

covering the groove

Figure 11

(b)

After the gasket tape has been placed around the

entire circumference, overlap the starting end of the

end of the tape by a minimum of 0.44” (11,2 mm).

See Figure 9. Be sure to smooth the tape at the

overlap transition in order to get a good seal.

No air gaps or bubbles should be present.

(c)

Repeat steps (a) and (b) in Section 4.5.5.4 for the

outer sealing area nearest to the outer diameter of

the IRON, again using the edge of the water cavity

as a guide.

4.5.5.5 Proceed to Section 4.5.7 to complete the

wear plate (3) replacement.

Caution

Before the gasket tape is covered with the wear

plate, the sealing surface should be protected to

prevent contamination from dust, dirt or oils.

No additional cleaning or liquid should be applied

to the surface of the IRON or gasket tape.

4.5.6 Assembly with Loctite Superflex

®

#596 Sealant

4.5.6.1 Clean and completely dry the sealing surfaces at the

I.D. and O.D. on the pressure plate (14), reaction

plate(s) (31) and end plate (117). These surfaces

should be free of nicks and scratches to prevent

leaks. Minor nicks and scratches may be filled with

Loctite Superflex

®

#596 Sealant during assembly.

4.5.6.2 Apply a uniform bead of Loctite Superflex

®

#596

Sealant in the grooves of the pressure plate, reaction

plate(s) and / or end plate. Recommended bead

diameter is 0.060" - 0.090" (1,5 mm - 2,3 mm) for

all sizes 24” and 36”. For the 48”size, refer to

procedure 4.5.6.3 for proper sealant application

procedure. For the 24” and 36”, skip to capitalize

section 4.5.7 after application of sealant.

Caution

Loctite Superflex

®

#596 Silicon Sealant will begin to

set up and skin over in approximately 10 minutes.

The wear plate must be fastened to the mating

component within 10 minutes of applying the sealant.

4.5.6.3 The 48WCSB tensioner / brake assembly incorporates

a dual groove for both the Loctite Superflex

®

#596

Sealant and an O-ring. An initial bead of sealant

0.030" - 0.060" (0,7 mm - 1,5 mm) in size must be

applied to the bottom of the deep groove in order to

hold the O-ring in place. See Figure 12.

Summary of Contents for Airflex WSB11206

Page 1: ......