25

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

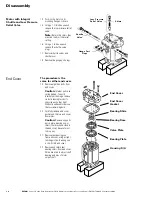

18. Install valve plate dowel pin in

the face of end cover.

19. Using petroleum jelly, lightly

coat side of valve plate facing

the end cover to hold valve

plate during assembly. Install

valve plate over bearing cup,

aligning it with dowel pin.

Valve parts must rest flat and

be flush with end cover.

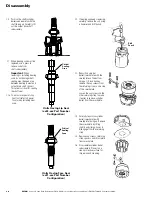

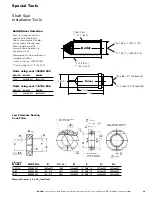

Input Rotation

Valve Plate

Metering

Slots

Valve Plate

Rotation

Metering

Slots

Metering

Slots

Pump valve plates are all uni-

directional and motor valve

plates are bi-directional. The

pump valve plate is identified

by two metering slots and

rotates clockwise. The motor

valve plate has four metering

slots and is bi-directional.

Pump and motor valve plates

are not interchangeable.

Note: Use extreme care

when handling all close

tolerance internal parts of

motor. Keep parts clean.

Assembly

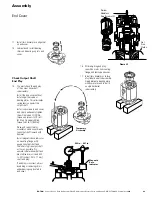

20. Holding the valve plate firmly

in position, install end cover

on housing.

21. Install cap screws in end

cover. Tighten them slowly and

evenly.

Torque the cap screws in a

star pattern. Models 33/39/46

should be torqued to 39 lb-ft

[53 Nm]. Models 54/64 should

be torqued to 63 lb-ft [85 Nm].

Torque each screw a second

time to compensate for gasket

compression set.

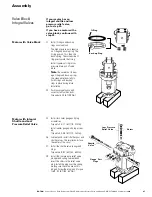

If you have a motor with a

face seal, use the following

procedure. If you have a

motor with a lip seal, use the

procedure on page 24.