21

OPERATING

SEQUENCE

The Easy Radiant gas burner is a very simple device. The normal sequence of events

during ignition and operation of the burner is as follows:

1.

The heater is energized by means of a thermostat or switch.

2.

When 24 volts is applied to the module, the module will energize the blower and

close the airswitch.

3.

The current flows and energizes the igniter and reaches ignition temperature. No

gas flows until the valve is energized and opened.

4.

Air pressure generated by the blower will cause the normally open combustion

pressure switch to close. The combustion pressure switch is set to allow the

normal rate of combustion air to flow into the combustion chamber. Any

restriction or blockage will cause the pressure switch to open and shut down the

entire system.

5.

The current passes through the blocked flue pressure switch, which is normally

closed. Any blockage or restriction will cause the pressure switch to open and

shut down the entire system.

6.

After 17 seconds, the valve is energized and opened. Gas flows through the

burner and is ignited.

7.

The power is removed from the igniter. The flame sensor is utilized. As long as a

flame is present, the valve is held open. If the flame is lost, the control acts to

close the valve within one second and a new trial sequence to start up is initiated.

8.

If ignition is not achieved, or flame is not sensed, then the control closes, the gas

valve, and attempts ignition a second time, and if necessary a third time. If

ignition is not achieved after the third try, the control goes into lockout for 30

minutes and power must be interrupted before trying again. At this point it is

suggested that an authorized service person be contacted to inspect and test the

controls.

9.

The heater should continue to function until power is interrupted either by the

thermostat being satisfied or manually disconnected.

NATURAL

GAS

AND

LIQUID

PROPANE

CONVERSION:

1.

Turn off gas supply at the appliance service valve.

2.

Remove regulator cap screw and pressure regulator adjusting screw

3.

Replace the existing spring with replacement spring.

4.

Re-install regulator cap screw and pressure regulator adjusting screw.

5.

Replace gas orifice with the one provided by the manufacturer.

6.

Check the regulator setting using a manometer.

7.

Mount the conversion label on the gas control

8.

Mount the new rating label on the heaters

Summary of Contents for Middleman EZM-100-50

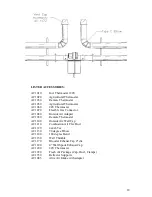

Page 17: ...17 VENTING OPTIONS...

Page 19: ...19...

Page 20: ...20...

Page 25: ...25 Middleman single stage wiring diagram...

Page 26: ...26 Middleman LTH dual input wiring diagram...

Page 28: ...28...