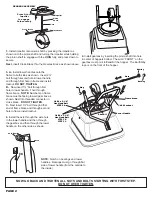

Axle

Bushing

Bearing

Frame brace

1/4-20 Locknut

Lower Handle

Bushing

Shut-Off

1/4-20 x 1-1/2”

Hex Head Bolt

STEP 5B

STEP 5C

1/4-20 x 2-1/4”

Hex Head Bolt

STEP 5A

Foot

3.

Install impeller onto pinion shaft by pressing the impeller as

shown onto the pinion shaft and turning the impeller while holding

the pinion shaft to engage with the

COIN

fully, and press down to

secure.

Next,

insert Cross Brace thru the Gearbox Brace as shown above.

FRON

T

Impeller

Cross Brace

GEARBOX ASSEMBLY

Gearbox Brace

Pinion

Shaft

Press & turn

Impeller

to engage

Coin securely

Coin

FR

ON

T

4.

Install gearbox by inserting the pinion shaft into hole

in center of hoppers bottom. The word “FRONT” on the

gearbox must point to

Front

of the hopper. The EarthWay

logo is on the front of the hopper.

Axle Bearing

Flat

Side

Notch

NOW GO BACK AND TIGHTEN ALL NUTS AND BOLTS STARTING WITH FIRST STEP.

DO NOT OVER TIGHTEN.

PAGE 2

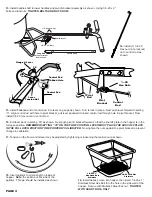

5.

A -

Install lower handles onto the

frame to both sides as shown. Insert 2¼”

bolt through second hole in lower handle

and through first hole in frame and install

locknut.

DO NOT TIGHTEN.

B -

Now insert 1½” bolt through first

hole in lower handle. Then through

frame brace.

NOTE:

Numbers on frame

brace must be facing toward gear box as

shown. Next into threaded connector in

cross brace.

DO NOT TIGHTEN

.

C -

Next insert 1½” bolt through other

end of frame brace and through second

hole in frame install locknut.

6.

Install the axle through the axle hole

in the lower handle and then through

the gearbox and then through the lower

handle on the other side as shown.

NOTE:

Notch on bearings and lower

handles. Bearings must go through flat

side of lower handle (from the outside to

the inside).