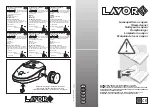

COMPONENTS

The following components are included in the kit (as illustrated below)

WD0001

Recovery Tank

WD0036

Crevice Tool

WDACC4 Extension Tubes x 2

WD0037

Floor Head

WD0029

Paper Filter

WD0045

Castors x 4

WD0030

Foam Filter

WD0048

Hose

WD0032

Rubber Band

WD0082

Motor Housing Assembly

WD0035

Hose Inlet

WD0147

Outlet Elbow

UNPACKING AND SETTING UP

1) Remove all packing materials and accessories and lift unit out of the box.

2) Release the two tank clips and lift the motor housing off from the recovery tank.

3) Remove all components from inside the tank.

4) Turn the tank upside down and insert the 4 castors. These should be pushed in hard until they stop.

Once installed these remain in place permanently.

5) Push the Hose Inlet into the hole in the side of the Recovery Tank. The Hose Inlet must be pushed in

from the outside of the Recovery Tank ensuring that the lug on the side of the Hose Inlet is lined up

with the slot in the hole in the Recovery Tank. Grasp the Hose Inlet from inside the Recovery Tank and

pull with an up and down motion to engage. Make sure that the clips on the top and bottom of the

Hose Inlet are fixed into place inside the Recovery Tank. Once installed the Hose Inlet can remain in

place permanently.

6) Fit the outlet elbow to the outlet on the motor housing. The outlet elbow can be used to deflect airflow

from the motor away from the work area.

3

WD0046-04-08.qxd 21/7/08 10:54 am Page 3