European Safety Systems Ltd.

Impress House, Mansell Road, Acton, London W3 7QH

www.e2s.com

Tel: +44 (0)208 743 8880

Document No. D190-00-651-IS

Issue 2

06-03-2023

Sheet 14 of 15

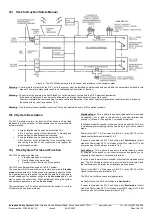

17) SIL 2 Specific Unit Mounting Requirements

The sounder should be mounted no closer that 5m from a sounder source of similar SPL output. This is to ensure false tone activation does not occur

when the unit is monitoring the tone pulse duration and tone failure.

18) SIL 2 Reliability Data

Reliability and Functional safety IEC/EN61508 which has been assessed and is considered suitable for use in low demand safety function:

1.

Random Hardware Failures and Architectural constraints (route 1

H

)

2.

As an unvoted item (i.e. hardware fault tolerance of 0) at SIL 2

The product was assessed against failure modes:

•

Failure respond to an input with a correct tone.

•

Failure to respond to an input even with an alternative tone.

•

Spurious sound output despite no input.

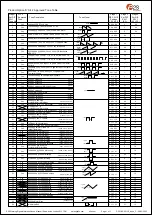

D1xS1FDC024-S/D1xS1RDC024-S (Failure to Sound)

Integrity in respect of failure to release

SIL 2

Total Failure rate

0.447 pmh

“hazardous” failure rate (revealed)

0.443 pmh

“hazardous” failure rate (unrevealed)

0.004 pmh

“safe” failure rate (revealed)

0.002 pmh

“safe”

failure rate (unrevealed)

0

Diagnostic Coverage

99%

System type

B

Hardware Fault Tolerance

0

Safe Failure Fraction

>99%

PFD (hazardous failure)

3.3 x 10

-5

Proof Test Interval

Up to 1 year

D1xS1FDC024-S/D1xS1RDC024-S (Failure to Sound or Incorrect tone)

Integrity in respect of failure to release

SIL 2

Total Failure rate

0.464 pmh

“hazardous” failure rate (revealed)

0.455 pmh

“hazardous” failure rate (unrevealed)

0.009pmh

“safe” failure rate (revealed)

0.002 pmh

“safe” failure rate

(unrevealed)

0

Diagnostic Coverage

98%

System type

B

Hardware Fault Tolerance

0

Safe Failure Fraction

>97%

PFD (hazardous failure)

5.2 x 10

-5

Proof Test Interval

Up to 1 year

Table 6: SIL 2 Failure Rate

19) Synchronised Operation

All D1xS1FDC024-S/D1xS1RDC024-S alarm horn sounders connected to the same power supply and set to the same alarm tone will provide a

synchronised output when activated.