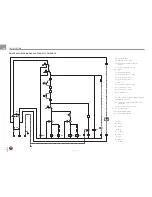

101,6 mm

101,6 mm

48,4 mm

48,4 mm

763 mm

763 mm

442 mm

332 mm

185 mm

370 mm

105 mm

E-Tech W

: 664Y6500 • B

en

10

EN

FR

NL

ES

IT

DE

PL

RU

INSTALLATION

DIMENSIONS

Min.

25 mm

Min.

400 mm

Min.

200 mm

WALL MOUNTING

• The boiler must be fixed to a non flammable

wall.

• Observing the clearances shown below, drill 2

off 14mm x 100mm holes.

• Fit the 2 bolts supplied and hang the wall

bracket.

• Fit washers and nuts

• Hang the boiler

FROST PROTECTION

the boiler is NOT fitted with frost protection. If the boiler is being installed in a position where freezing

could take place, then a suitable external frost thermostat should be fitted.

CONNECTING TO THE SYSTEM

the boiler is designed to operate on a sealed system (ie. no open vent or feed and expansion cistern)

Hot water expansion within the system is taken up by the internal 10 litre expansion vessel. This is

suitable for systems up to 160 litres capacity. If the system capacity is more than this then an additional

expansion vessel may be required.This can be fitted external to the boiler at a convenient place on the

pipework.

Please note that the circulation pump is fitted to the flow connection.

INSTALLATION ROOM

The appliance must be positioned in such a way as to be easily accessible at all times. In addition, the

following minimum distances around the appliance must be complied with.