6

BG 5913.08/_2 _ _ _ / 03.11.20 / 314A

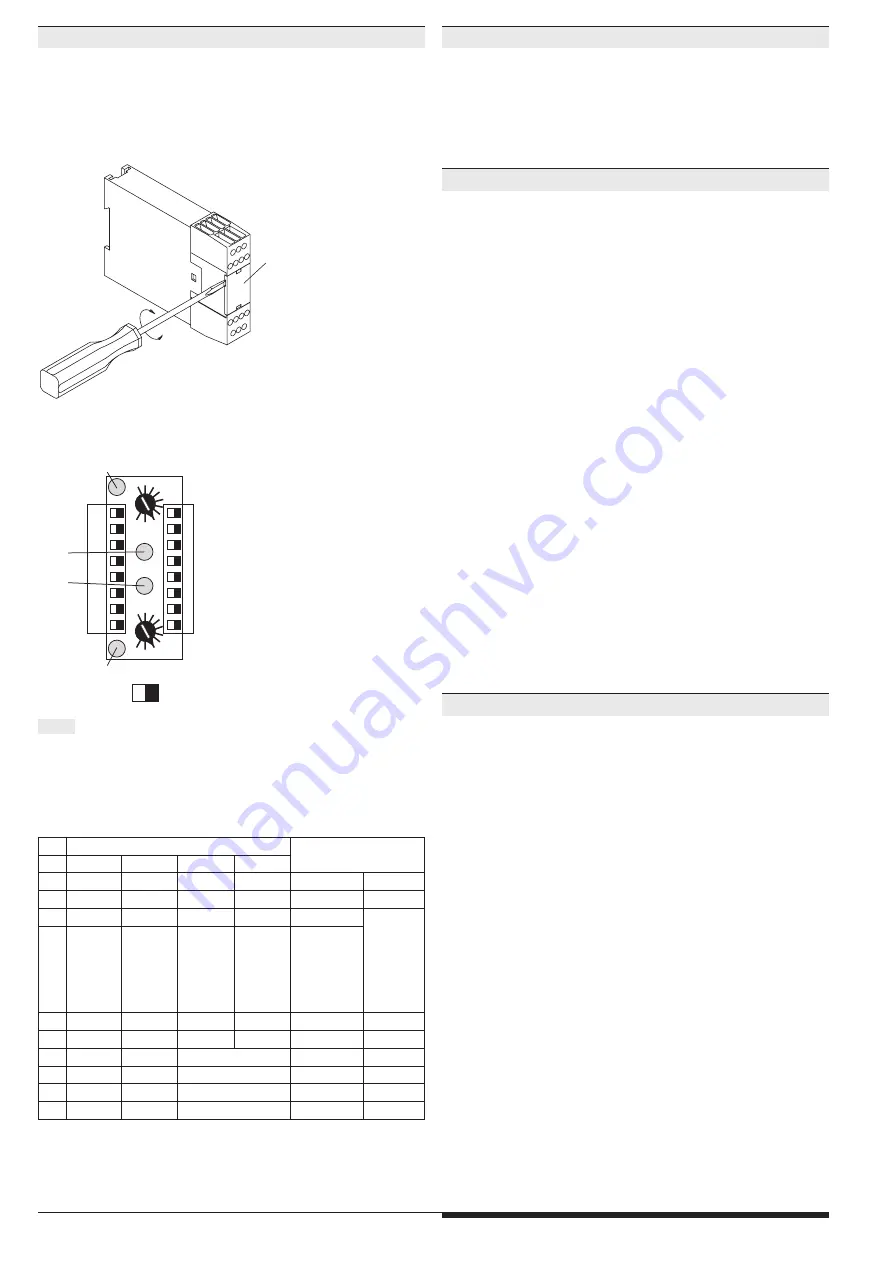

The module is assigned to the start inputs and the safety outputs via the

DIP switches.

The combinations of individual functions are set via the rotary switches.

To prevent accidently adjustments, these elements are covered by a front

plate and are redundant.

plate

M2926_

a

M8941_b

0

2

3

4

7

8

9

0 1 2

5

6

7

9

1

2

3

4

5

6

7

8

output

Mod3

Mod2

Mod1

Base

Mod3

Mod2

Mod1

Base

S1

S2

1

2

3

4

5

6

7

8

start

input

T1

T2

T3

T4

T1

T2

T3

T4

green LED "en 1"

green LED "en 2"

white LED

"run 1"

white LED

"run 2"

off

on

•

Settings to the unit must be performed by skilled personnel while

the unit is disconnected.

•

Before the front cover is removed, antistatic precautions must be

observed.

Note:

Setting of the Modules

Sw.

Function at Terminals

Start behavior of the LC

/ E-Stop

S12-S14 S22-S24 S32-S34 S22-S24

0

Gate

Gate

E-Stop

LC

Autostart

1

Gate

Gate

E-Stop

LC

Manual Start

2

E-Stop

E-Stop

E-Stop

E-Stop

Autostart

Enabling

only

when

all other

modules

permit

enabling

3

E-Stop

E-Stop

E-Stop

E-Stop Manual Start

4

E-Stop

E-Stop

E-Stop

E-Stop

Autostart

5

E-Stop

E-Stop

E-Stop

E-Stop Manual Start

6

E-Stop

E-stop

Two-hand IIIC

Autostart

7

E-Stop

E-stop

Two-hand IIIC

Manual Start

8

Gate

Gate

Two-hand IIIC

Autostart

9

Gate

LC

Two-hand IIIC

Autostart

Each function activates an enabling signal in the module software. The

control unit is permitted to enable the assigned safety outputs only after

all 3 (for two-hands control) or 4 enablings have been given.

With the exception of two-hand control, each function works independently.

The assigned safety outputs are enabled if the precondition for enabling

has been met for all functions.

This function will only work when the other two functions have already

permitted enabling. To provide for enabling, the two buttons must be

pressed within 0.5 s. As soon as one of the other function reacts, the two

buttons must turn inactive before the others can be enabled again. Only

after that, the buttons can be activated once more from an inactivated state.

The unit must be connected as specified in the application examples.

When the operating contacts are connected in parallel or in series, safe

functioning of the unit is cancelled.

The two-hand buttons must be designed and arranged in such a way as to

ensure that they cannot be disabled with easily, or pressed unintentionally.

The safety distance between the push buttons and the place of danger

must be large enough to make sure that after releasing a button, the place

of danger can only be reached after the dangerous movement has stopped.

The safety distance “S” is calculated according to the following formula:

S = V x T + C, where

a) gripping velocity V = 1 600 mm/s

b) overtravel time T (s)

c) and safety factor C = 250 mm.

When any access into the danger area, with operating keys pressed, is

safely prevented, e.g. by a protective cover for the keys, the safety factor

C may be set to the value 0. Generally, the minimum safety distance must

be 100 mm. In this respect, also see DIN/EN 574.

The two-hand control must be released when another function module

which affects the same outputs does not permit enabling.

The system may comprise only one function module with two-hand control.

The safety gate function always permits enabling if both contacts change

from inactive to active state within 3 seconds. If the second contact reacts

later, both changeover contacts must turn inactive before they can be

enabled again.

When activating the system, press the start button to simulate the compul-

sory opening and re-closing of safety gates which have been kept closed

since the system has started.

This simulation is possible only before enabling has been permitted for

the first time, and as long as both safety gate contacts remain closed as

well. As soon as a contact opens, simulation of the safety gate function

is no longer possible.

Setting of the Module

Functional Principle of Combined Inputs

Function of the Two-Hand Control

Safety Gate Function