19

CC 222/222C - CC 232/232C - CC 322 M222EN5

EVERY 500 HOURS OF OPERATION (Every three months)

Drum - oil level

Inspection - filling

Split drums -

Lubrication (CC 232 only)

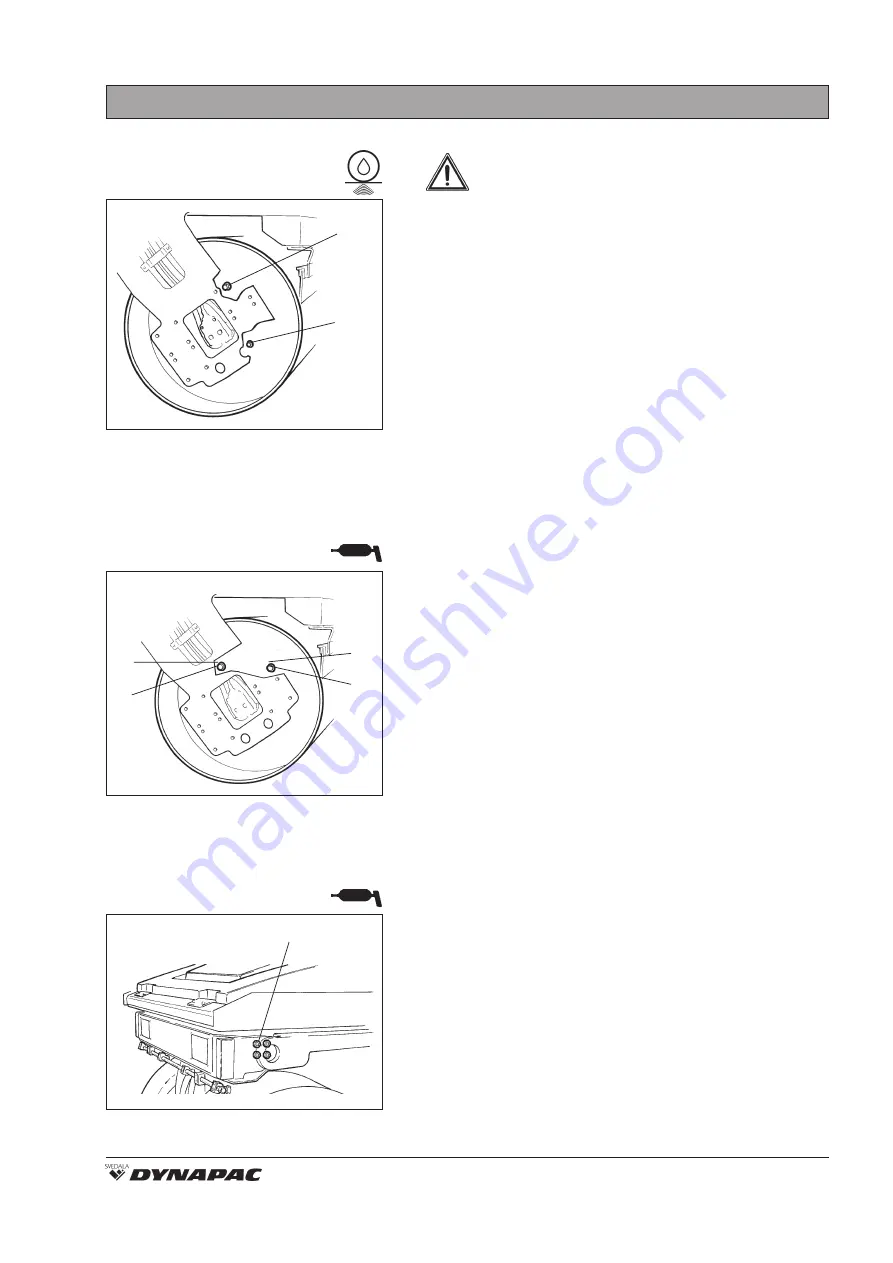

Fig. 30 Drum, drive side

1. Protective plugs

2. Grease nipples

Fig. 31 Rear drum, right side

1. Grease nipples, 4 off

1

Fig. 29 Drum, vibration side

1. Filler plug

2. Level plug

1

2

1

2

1

2

Pivot bearing (Optional) -

Lubrication

Grease each nipple (1) with five strokes of a hand-

operated grease gun.

Use grease according to the lubricant specification.

Position one drum at a time so that two protective plugs

(1) are accessible near the top of the drum.

Screw out the protective plugs and grease each nipple

(2) with five strokes of a hand-operated grease gun.

Refit the protective plugs and then reposition the drum

to grease the two remaining nipples.

Lubricate both drums.

Place the roller on a level surface. Switch

the engine off and push in the reserve/

parking brake knob for all checking and

adjustments on the roller, unless otherwise

specified.

Position the roller with the filler plug (1) - the large plug -

straight up.

Wipe clean around the level plug (2 - the small plug -and

unscrew it.

Make sure that the oil level reaches up to the lower

edge of the hole, top off with fresh oil as required. See

Lubricant specification.

When removing the filler plug, wipe it clean from any

metal on its magnet.

Make sure that plug seals are intact and replace with

new seals as required.

Refit the plugs.

Check both drums.

Drive a distance and make sure that the plugs are tight.

WARNING

Summary of Contents for CC 222

Page 2: ...19 ILF015WO1...