- 2 -

M965534 Rev. 1.9 (4/18)

2

3

1

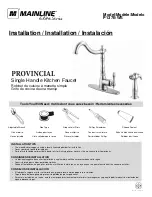

TEE ASSEMBLY

INSTALL VALVE BODIES

• Insert SPOUT ASSEMBLY

(1)

and

CABLE CONNECTOR

(2)

through

center hole, making sure O-RING

SEAL

(3)

is properly seated in

SPOUT BASE

(4)

groove.

• Assemble RUBBER WASHER

(5)

,

BRASS WASHER

(6)

and

LOCKNUT

(7)

onto SPOUT

SHANK

(8)

from under side

of sink. Make sure SPOUT

(1)

is centered in the mounting

hole and the slot in the BRASS

WASHER

(6)

faces toward

the front of the sink.

• Tighten LOCKNUT

(7)

firmly.

SPOUT ASSEMBLY

CAUTION

Turn off hot and cold water

supplies before beginning.

• Thread TEE BODY

(1)

COUPLING NUT

(2)

to

SPOUT SHANK

(3)

. Tighten with wrenches.

• Thread LOCKNUT

(1)

to bottom of VALVE BODY

(2)

. Make sure

SPACER

(3)

, BRASS WASHER

(4)

and RUBBER WASHER

(5)

are installed.

• Insert VALVE BODY

(2)

through mounting hole from underside

of lavatory or mounting surface.

Note: VALVE BODY marked Hot (Red Dot) is installed in the left

Mtg.hole, VALVE BODY marked Cold (Blue Dot) in the right

when facingfront of fitting. Maximum mounting surface thickness

is 1-3/4

"

(44mm).

• Install STOP RING

(6)

onto VALVE BODY

(2)

.

• Thread FLANGE

(7)

onto VALVE BODY

(2)

until tight aganist

the STOP RING

(6)

.

• Align VALVE BODY

(2)

and from below tighten LOCKNUT

(1)

to secure VALVE BODY

(2)

.

INSTALL HANDELS

• Install SEAL

(8)

into base of HANDLE ESCUTCHEON

(9)

.

• Turn VALVES to off position. Align HANDLE ASSEMBLY

(10)

and push down onto spline of VALVE BODY

(2)

. Thread HANDLE

ESCUTCHEON

(9)

tight against mounting surface.

• Installation for the Cold Water Valve is the same.

HOSE CONNECTIONS

• Tighten COUPLING NUT (

11)

on SUPPLY HOSE

(12)

to

OUTLET

(13)

making a water tight connection.

Important: Loop SUPPLY HOSES (12) as shown so they

do not kink.

1

SLOT

3

5

7

2

6

8

4

1

3

2

1-3/4'' (44mm) MAX.

MOUNTING SURFACE

SPLINE

RED DOT

STOP RING

CROSS HANDLE

ASSEMBLY

1

2

HOT

13

5

11

COLD

12

16

3

4

7

8

6

9

10

CYLINDER

HANDLE

ASSEMBLY

TRI-SPOKE

HANDLE

ASSEMBLY