11

Fire Hazards!

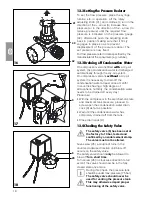

8.2 Compressed-air Connection

A standard feature of the compressor is a

control unit comprising the following:

pressure switch (11), safety valve (6),

compressed-air connection coupling (20) and

pressure gauge (7).

• Slip flexible pressure hose (ø 8x3x14) onto

connecting socket of pressure reducer and

secure with hose clip (21) to prevent

slipping off.

A flexible pressure hose fitted between

the firmly installed compressed-air

tube and the compressor serves to

prevent transmission of vibration and

thus reduces noise.

8.3 Electrical Connection

Connection up to the voltage supply

system may only be carried out by a

suitably qualified electrician

(with exception of those stations

supplied ready for plugging into an

earthing-contact type socket or CEE

socket, depending on the version of

the compressor).

The 400 V version of the compressor is

supplied fitted with a CEE connector, and the

230 V version with an earthing-contact type

plug. The regulations of local power supply

companies must definitely be observed.

The mains voltage and frequency must conform

to the data specified on the rating plate.

No connecting cable must be

allowed to run across the unit. The

hot surfaces of the compressor

might otherwise cause damage to

the cable insulation.

• If the unit is permanently connected up to

the voltage supply system, provision must

be made for a power disconnecting device

with a contact opening width of at least

3 mm (e.g., a power circuit breaker).

• If the unit is connected up to the voltage

supply system by means of a plug-type

connector, ease of access must be provided

to the socket for safety reasons, enabling

the unit to be disconnected safely from the

mains in cases where danger situations

arise.

• The corresponding circuit must be protected

by a fuse consisting of an LS-switch10 A

(characteristics B, C, and D) supplied and

20

21

11

7

6

4

3

5