Displacement Pump Repair

Intake valve repair

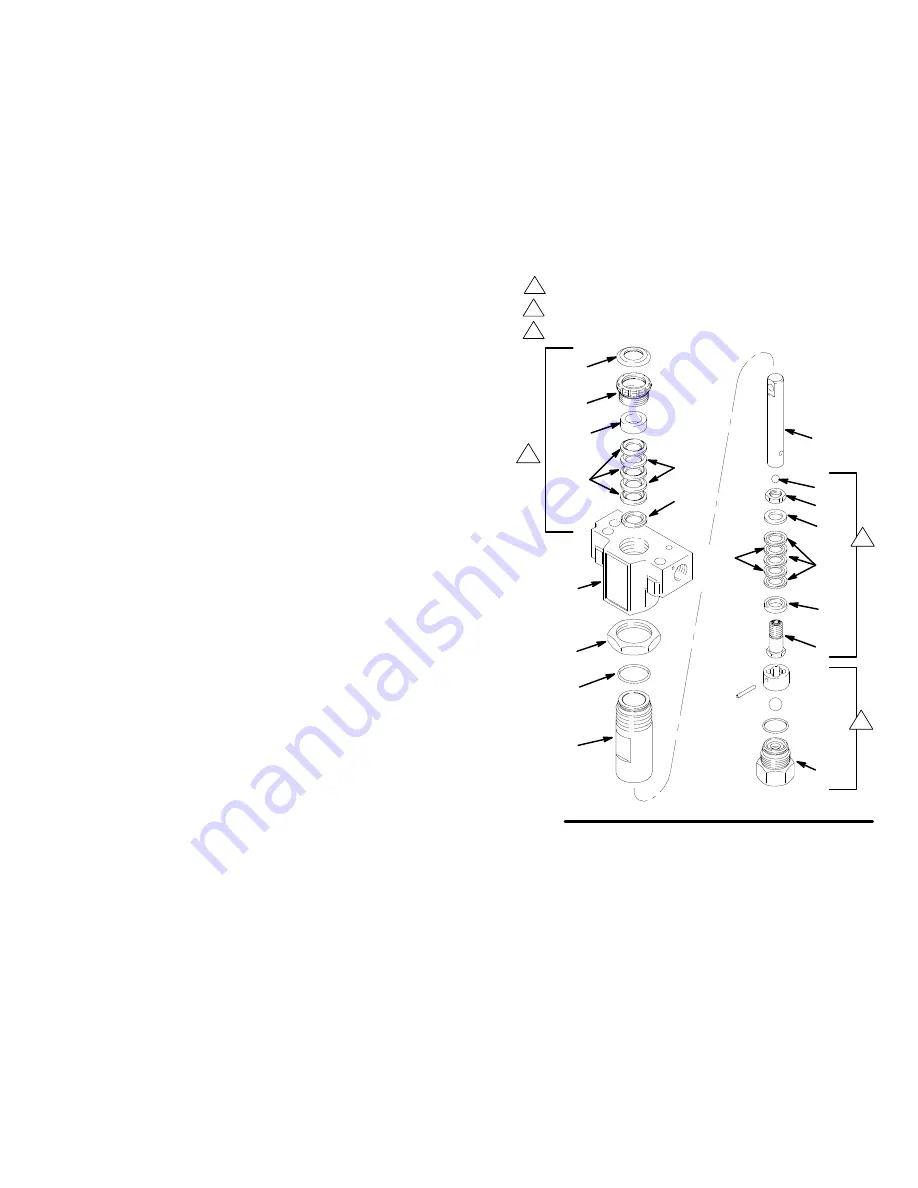

(See Fig. 17)

1.

Remove the suction hose. See Step 2, Removing

the pump.

2.

Unscrew the intake valve (118). Remove the

o-ring (119*), ball guide (120), stop pin (122*) and

ball (121*) from the valve.

3.

Clean and inspect the parts for wear or damage.

Replace parts as needed. Use a new o–ring

(119*). If no further service is needed, reassemble

the pump.

Disassembling the pump

(See Fig. 19.)

1.

Remove the intake valve (118). See page

2.

Loosen the packing nut (102) and plug (123).

3.

Use a plastic mallet to tap the piston rod (107)

down, and then pull the rod out through the bottom

of the cylinder.

4.

Remove the packing nut (102) and throat pack-

ings.

5.

Loosen the jam nut (117). Remove the cylinder

(115) and the o-ring (116*).

6.

Clamp the flats of the piston rod in a smooth jaw

vise. Use an open-end wrench to loosen the nut

(110) and then unscrew the piston valve (108).

7.

Remove all parts from the piston valve (108).

Reassembling the pump

NOTE: Alternate plastic and leather packings. See Fig.

19. The lips of the throat V-packings face down. The

lips of the piston V-packings face up. Incorrect installa-

tion damages the packings and causes pump leakage.

NOTE: Soak the leather packings in oil before reas-

sembling the pump.

1.

Check the outside of the piston rod (107) and the

inside of the cylinder (115) for wear. Replace worn

parts to ensure a good seal with the new packings.

2.

Stack these parts onto the piston valve (108) one

at a time: the female gland (114*), alternately three

plastic (112*) with two leather packings (113*), and

the male gland (111*). See Fig. 19.

Fig. 19

01069A

107

109*

110

111

112*

114*

108

123

102

*103

*104

105*

106*

101

117

*116

115

118

*113

Throat packings

Piston packings

Intake valve