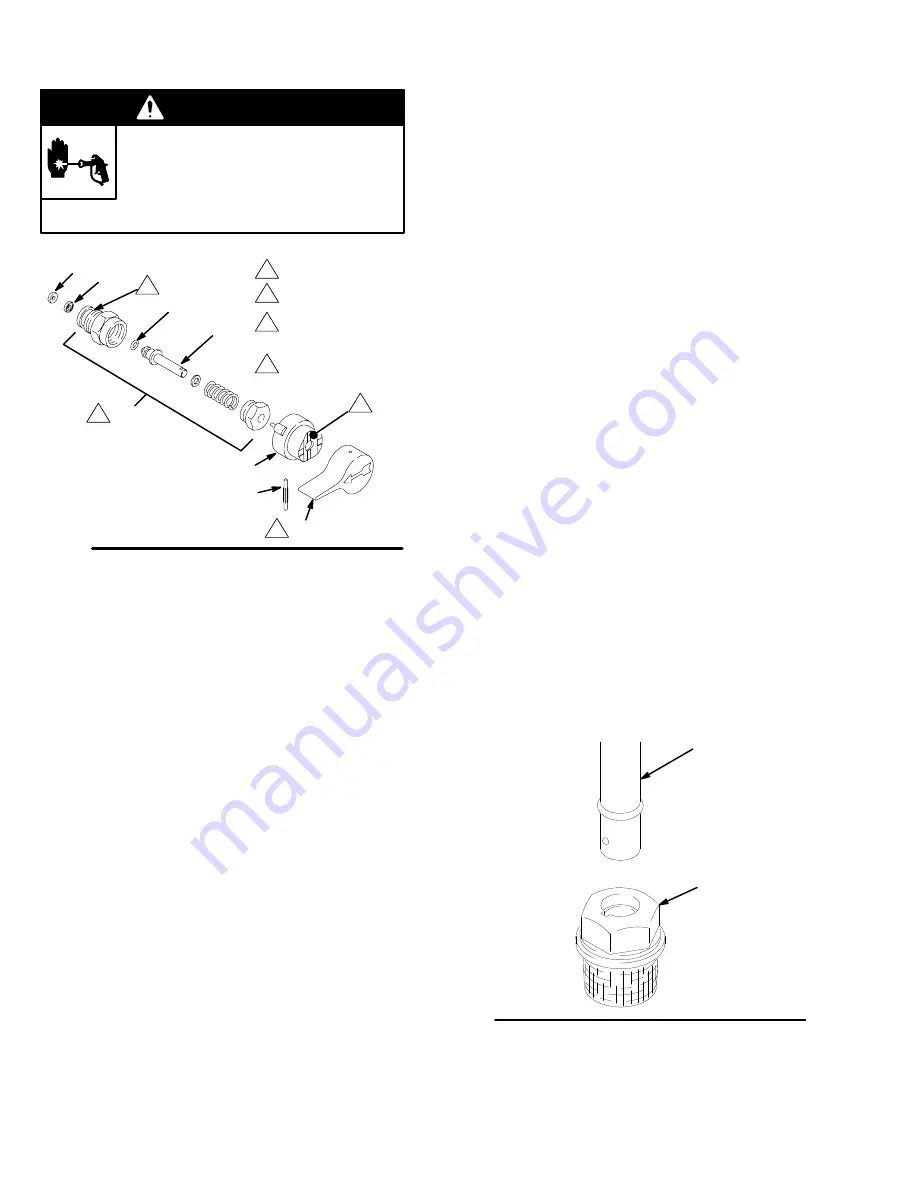

Drain Valve

WARNING

INJECTION HAZARD

To reduce the risk of serious injury,

whenever you are instructed to relieve

pressure, follow the Pressure Relief

Procedure on page 9.

44

42a

42b

43

45

Apply thread sealant

Handle shown

in closed position

Apply grease

to face of base

42

Torque into pump

manifold to 185 in–lb

(21 N.m)

42c

42d

Fig. 32

02819

1

3

4

2

1

2

3

4

1.

Turn the handle (45) to the closed position. Drive

out the pin (44). Remove the handle.

2.

Remove the base (43).

3.

Unscrew the drain valve (42). The gasket (42a)

and seat (42b) will stay in the valve.

Repair

1.

Unscrew the spring retainer from the valve body.

Remove the spring, washers and stem/ball. Clean

any debris from the ball or seat area.

2.

If replacing the gasket (42a) or seat (42b), pry out

the gasket.

NOTE: Whenever the gasket (42a) is removed, re-

place it with a new one.

3.

Coat the o-ring (42d) with grease. Press the stem

into the valve body. Install the spring, washers and

spring retainer into the valve body.

4.

Place the seat (42b) in the valve body so the

lapped side is toward the ball. Apply a small

amount of grease to the new gasket (42a) and in-

stall it in the valve body.

NOTE: The gasket will protrude from the end of the

valve until the valve is tightened into pump, which cor-

rectly seats the gasket.

Replacement

1.

Apply a small amount of thread sealant (42e) onto

the valve (42) threads. Tighten the valve into the

pump manifold to 185 in–lb (21 N.m).

2.

Lightly grease the face of the base (43) and install

the base. Turn the stem so the pin hole is vertical.

3.

Securely install the handle (45) and drive pin (44).

Inlet Strainer Installation/Removal

Installation (Fig. 33)

1.

Align the keyway in the strainer (39) with the small

nub near the end of the suction tube (32).

2.

Push the strainer over the nub and up to the suc-

tion tube’s raised band. While holding the strainer

against the band, rotate it about 1/2 turn in either

direction (a wrench may be necessary).

Removal

1.

With a wrench or the hand, turn the strainer (39) in

either direction until the keyway aligns with the

raised nub in the suction tube (32). A sudden re-

lease in turning resistance will be felt when the

parts align.

2.

Pull, or tap, the strainer straight off the suction

tube.

39

Fig. 33

04717

32