12

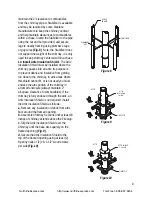

Top Collar Section to the field-fabricated chase

top with sheet metal screws or rivets (Fig. 14).

Seal Chase Top Collar Section to chase top with

non-hardening waterproof sealant to ensure a

weather tight connection. Additional screening

as needed for field-fabricated chase covers is

allowed. Additional ½” minimum spacers can be

field-fabricated as needed out of 24 GA sheet

metal or other suitable non-combustible material.

Additional non-combustible structural supports

can be field-fabricated to help support the chase

top flashing if needed, provided the air ventilation

requirements are maintained. Secure the Chase

Top Flashing to the chase with at least (3) screws

or nails per side. When installed, the bottom of

the Chimney Cap must be at least 6” above the

Chase Top Flashing (Fig. 15).

13. Finish Top: Apply a non-hardening

waterproof sealant around the chimney at the

point where the Storm Collar will meet the

chimney just above the Flashing (Fig. 15). Slide

the Storm Collar down over the chimney to the

top of the Flashing. The Storm Collar must be

installed 1” off the Chase Top Flashing to provide

proper ventilation (Fig. 15). Tighten the bolts

of the Storm Collar and seal the Storm Collar

against the Chimney with sealant. Be sure

Chimney and Offsets are properly supported.

Attach the Chimney Cap onto the top of the

chimney by setting the female end of the Cap

onto the male end of the last Chimney Section.

Secure the Cap by using (4) sheet metal screws

provided (Fig. 16). Do not push down from the

top portion of the cap as this may damage the

cap. push from the lower section of the Cap if

needed. The Chimney Cap can be removed for

chimney cleaning as described in the Chimney

maintenance section of the instructions.

14. Enclosures: enclose chimneys where

they pass through occupied spaces, including

closets. Always maintain at least a 2-inch

Figure 16

TERMINATION

CAP

Figure 14

Figure 15

6" MIN.

COLLAR

SEALANT

STORM

OPENING

ABOVE ROOF

3' MINIMUM

CHASE TOP

COLLAR

SEALANT

SCREW OR

POP-RIVET

NorthlineExpress.com

http://www.northlineexpress.com

Toll-Free 1-866-667-8454