Start-up Manual

89475/119 ETM

6

Duplomatic MS S.p.A.

All rights reserved.

Characteristics

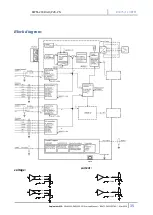

This electronic module has been developed for controlling hydraulic positioning drives.

Both axes can be controlled independently or also be driven in synchronous mode via ProfiNet.

The differential outputs are provided for the control of proportional valves with integrated or external

electronics (with differential input). Alternatively,

the output can be parameterized to 4… 20 mA. This

module is intended for the connection with analogue position sensors 0...10V or 4...20mA (scalable) or

digital SSI sensor interfaces.

The internal monitoring sends information about error and operating states via the ProfiNet to the Master

controller. The operational readiness is reported via a digital output, too.

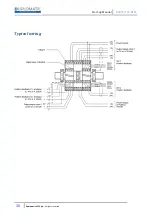

Typical applications

: Positioning control or synchronization control with hydraulic axes.

Features

•

Two independent positioning axes

•

Can be combined for synchronized control

•

Command position value parameter, actual value response, control bytes and status bytes

via fieldbus (ProfiNet IO)

•

SSI-Sensor interface or a

nalogue sensor interface (0….10V or 4…20mA)

•

Simple and user-friendly sensor scaling

•

Position resolution of 0.005 mm/s

•

Principle of stroke-dependent deceleration for the shortest positioning time or NC profile

generator for constant speed

•

Highly accurate positioning

•

Advanced position control with PT1 controller, Drift compensation and Fine positioning

•

Superimposed synchronization controller with PT1 (optimal for hydraulic applications)

•

Optimal use with zero lapped control valves

•

Synchronization control in Master/Slave or average value mode

•

Fault diagnosis and extended checking function

•

Simplified parameterization with EWMPC/20 software