9

● Pull rightward the switch1

(

Fig25 1c

)

, the tool

head must rotate counterclockwise by 180°

● Pull leftward the switch1

(

Fig25 1d

)

, the tool

head must rotate clockwise by 180°

● Pull rightward the switch 2

(

Fig 23

)

the tool

arm must move rightwards.

● Pull leftward the switch 2

(

Fig 23

)

the tool arm

must move leftwards.

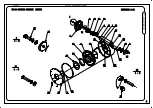

2 Check if the movement directions of the carriag

(

5

)

and tool arm

(

7

)

is correct

(

see Fig 23

):

●

Push leftward switch 3, carriage move

leftward.

●

Push rightward switch 3, carriage move

rightward.

●

Push upward the switch 3, the tool arm move

upward

●

Push downward the switch3, the tool arm

move downward

3 Check if the function of the center chuck is

correct

(

see Fig 22

)

:

●

Push the switch4 leftward, the chuck will

open.

●

Push the switch4 rightward, the chuck will

close.

●

Step the pedal switch at the b side

,

the chuck

will rotate clockwise.

●

Step the pedal switch at the c side

,

the chuck

will rotate counterclockwise

4 Check the vertical movement of the tool arm and

the

rotating

function

of

the

tool

hea

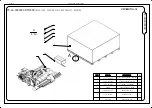

Fig 26 Valve mounting board

Adjust the throttle valve of the valve mounting

board

(

Fig 26

),

the tool arm rising speed will

increase or decrease.

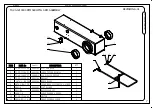

Fig27 direction switching cylinder

Adjust the throttle valve of the direction switching

cylinder (Fig 27) to increase or decrease the

rotating speed of the direction changing device of

the tool head.

5 Tire clamp function

:

Adjust the hydraulic clamp force of the chuck

:

We can change the clamp force of the chuck by

adjusting the pressure decrease valve rotation

handle of the hydraulic power unit. The pressure

ranges 130 bar, which can be displayed via

hydraulic gauge. When dismount/mount the light

alloy rim or the rim of very thin

,

you should

Throttle valve

Throttle valve

DTM590

DUNLOP GARAGE EQUIPMENT