Product Holding Unit

Restaurant Equipment Manual

16

Control Programming

The electronic temperature control is pre-set at the factory to maintain the temperature at the

bottom center of the pan cavity at 190° F +/- 5° F. This temperature is the result of many hours

of food testing at the Burger King test laboratory. There are no operator temperature adjust-

ments that can be made. Because the electronic control uses a platinum type RTD sensor,

routine calibration is not required.

!DANGER!

LIVE ELECTRICAL COMPONENTS.

ONLY QUALIFIED SERVICE PERSONS SHOULD MODIFY CONTROL

TEMPERATURE PRESETS.

Flashing Lights

A

B

Top Shelf

X

Bottom Shelf

X

Temperature Programming

1. Remove cover from control side of the

Holding Unit and turn the Holding Unit on.

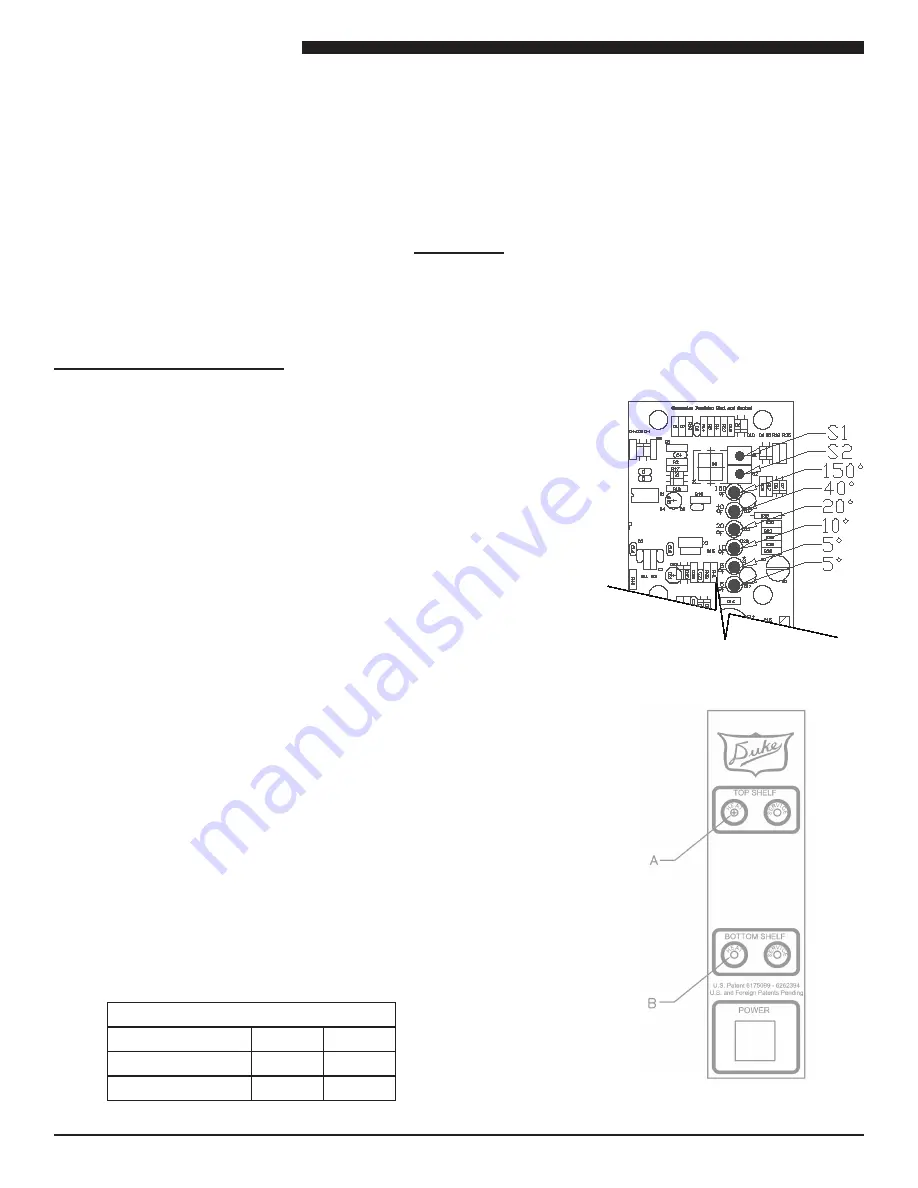

2. Locate the push button S1 and S2 on the rear

of the control. (see Figure 4.1)

3. Press and hold S1 until any LED on the rear

of the control illuminates. (approximately 5

seconds)

4. Observe the front of the control (Figure 4.2).

Press and release S1 on the back of the

control until the desired light on the front of

the control flashes. (see Table 1)

NOTE: To comply with NSF sanitation

requirements, do not set the control preset

temperature below 190° F.

5. Press and release S2 until the sum of the LED

values illuminated on the rear of the board

match the desired pre-set temperature.

6. Repeat steps 4 and 5 for each pre-set

temperature then press and hold S1 until no

LED on the rear of the control is illuminated

and the lights on the front of the board no

longer flash.

7. Replace cover on control side of the Holding

Unit.

Figure 4.1

Figure 4.2

Table 1