Page 32

6.

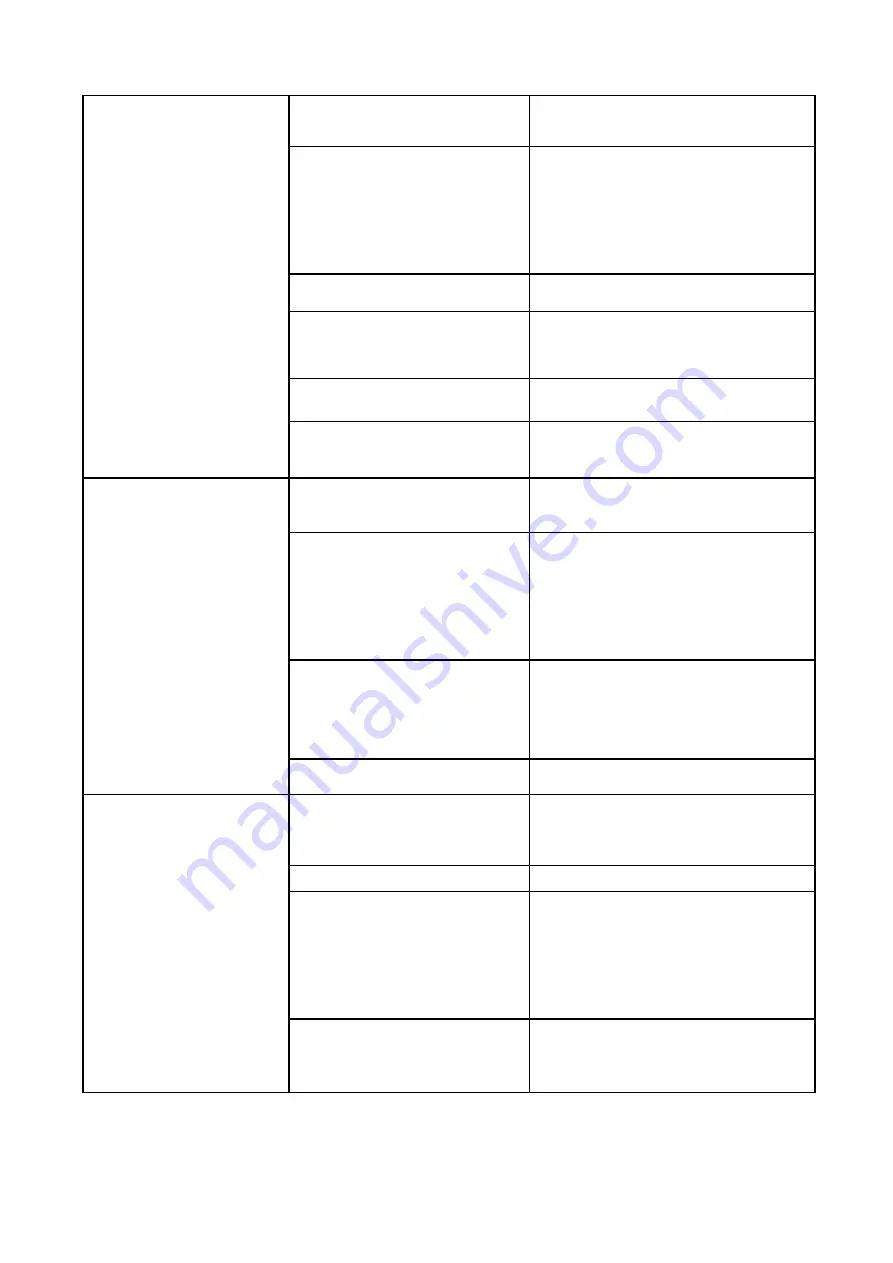

Hook lowers but will

not raise

A) Lifting motor overload

A) Reduce load to within rated

capacity of chain hoist.

B) Low voltage

B) Determine cause of low voltage

and bring up to within plus or

minus 10% of the voltage

specified

on

the

motor.

Measure voltage at the lifting

motor in terminal block power

input.

C) “UP” circuit open

C) Check circuit for loose

connections

D) Broken conductor in

pushbutton cable

D) Check each conductor in the

cable. If one is broken, replace

entire cable.

E) Worn overload limiting

clutch

E) Adjust or replace overload

clutch assembly.

F) Loose screw clamps

F) Ensure that screw clamps are

tightened on the terminal

blocks.

7.

Motor overheats

A) Excessive load

A) Reduce load to within rated

capacity of chain hoist

B) Low voltage

B) Determine cause of low

voltage and bring up to within

plus or minus 10% of the

voltage specified on the motor.

Measure voltage at the lifting

motor in terminal block power

input.

C) Frequent starting or

reversing

C) Excessive inching, jogging or

reversing should be avoided

since this type of operation will

drastically shorten the life of

motor and brake.

D) Brake dragging

D) Replace brake assembly

8.

Lack of proper lifting

speed

A) Chain hoist overload

A) Reduce load to within rated

capacity of chain hoist

B) Brake dragging

B) Replace brake assembly

C) Low voltage

C) Determine cause of low

voltage and bring up to within

plus or minus 10% of the voltage

specified on the motor. Measure

voltage at the lifting motor in

terminal block power input.

D) Overload limiting clutch

intermittently slipping

D) Adjust or replace overload

limiting clutch assembly.

Summary of Contents for DU903

Page 1: ...Page 1...