Page 26

HOOK INSPECTION

Hooks damaged from chemicals, deformations or cracks, or that have more than

a 10 degree twist from the hook’s unbent plane, excessive opening or seat wear

must be replaced. Also, hooks that are opened and allow the latch to not engage

the tip must be replaced. Any hook that is twisted or has excessive throat

opening indicates abuse or overloading of the unit. Inspect other load sustaining

parts, hook block screws, load pins and hook block bodies for damage.

Check to make sure that the latch is not damaged or bent and that is operates

properly with sufficient spring pressure to keep the latch tightly against the tip

of the hook and allow the latch to spring back to the tip when released. If the

latch does not operate properly, it should be replaced.

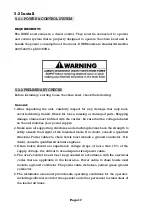

To Measure opening, depress latch against hook body as show.

Replace the hooks when opening is greater than 38mm.

CHAIN

1.

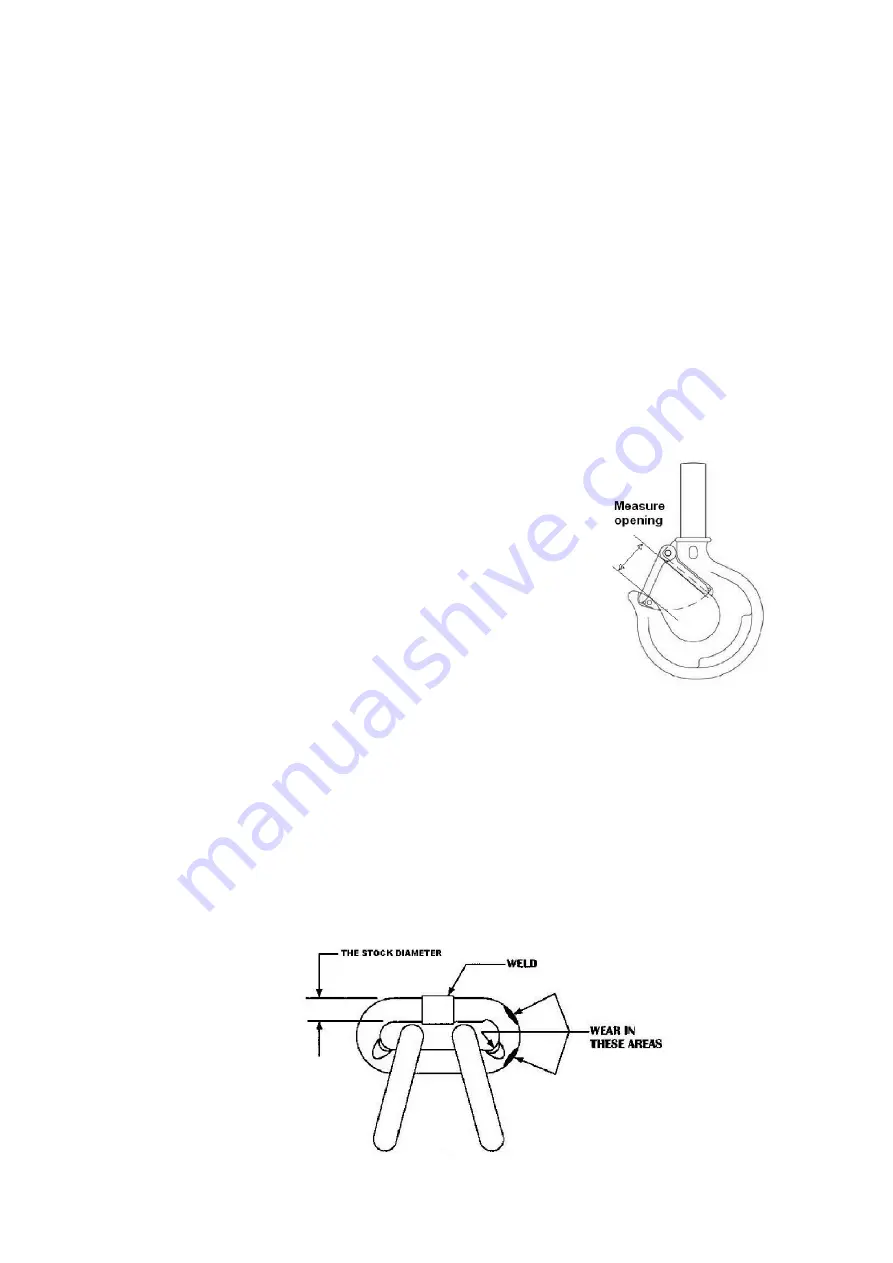

Clean chain with a non-caustic/non-acid type solvent and make a link by link

inspection for nicks, gouges, twisted links, weld splatter, corrosion pits, striations,

cracks in weld areas, wear and stretching. Chain with any one of these defects must

be replaced.

2.

Slack the portion if the chain that normally passes over the liftwheel. Examine the

interlink area for the point of maximum wear. Measure and record the stock

diameter at this point of the link. Then measure stock diameter in the same area on

a link that does not pass over the liftwheel and compare these two measurements.

Summary of Contents for DU903

Page 1: ...Page 1...