18

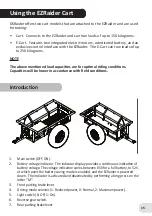

Pre-ride Inspection

A daily inspection prior to using the cart will contribute to its proper

functionality and driving safety.

WARNING

If a malfunction or suspicion of failure has been identified, the cart should not

be used until it has been repaired at an authorized DSRaider service center.

1. General check. A visual inspection of the cart, in order to identify a

malfunction or potential point of failure.

2. Stickers. All the warning stickers should be intact and readable.

3. Screws and nuts. Check all the visible screws and nuts. Tighten loose

screws as required.

4. Loading platform. Check that the loading platform is undamaged, and

that the payload materials are securely fastened to the platform.

5. Chassis and rack. Check the soundness of the cart’s chassis and rack

components. Ensure that there are no cracks or significant damage.

6. Interfaces. Check the points of interface between the EZRaider and the

cart. Make sure that the cart maneuvers freely and that the security pin

is locked in place.

7. Tires and wheels. Check that the tires are undamaged and that the air

pressure conforms to the specifications in the table below.

Driving on paved roads

PSI 10

Driving in rough terrain

PSI 6

Minimal air pressure

PSI 4

Air pressure during storage

PSI 30

A constant use of low air pressure requires the in-

stallment of a puncture-preventing substance inside

.the tires

Note that driving on tires with low air pressure raises

.energy consumption levels