Flowgrid Slam Shut | 15

Assembly of the Shut-off Valve

Refer to Figure 11 for this operation.

1. Install the (two) shaft bushings into the valve housing.

Align the cutaway section of the bushing toward center

wall of the housing so the bushing shoulder sits against

the housing wall

2. Hold the flapper so the lugs are down and slide them

between the two bushings just installed. Slide the shaft

into the valve housing, through the bushing and the first

lug on the flapper.

3. Place the left flapper spring between flapper lugs. The

straight spring leg should be against the bushing and the

center wall of the housing. The bent spring leg should be

against the back side of the flapper in the center. Slide

the shaft through the spring. Repeat the process for the

right flapper spring. Slide the shaft through the second

lug in the flapper and into the second bushing.

4. Have a second person hold the top face of the flapper

flush with the top of the valve body. Align the shaft so

the two pin holes align with the pin holes in the flapper.

Install the two split pins using a pin punch larger than the

pin hole in the flapper. Drive the top of the pins flush with

the top of the flapper surface when the flapper is pushed

down.

5. Lube the o-rings with lubricant supplied in the rebuild kit.

6. Install the appropriate o-ring on the rear reset nut. Screw

the nut on the end of the shaft.

7. Install the flapper seal into the seal retainer making sure it

is seated in the groove.

8. Using a 1/2 inch or 13 MM wrench turn the shaft clock-

wise so the top of the flapper is flush or below the top of

the valve housing.

9. Install the seal retainer with the flapper seal down onto

the slam shut body. The small flow hole in the seal goes

on the flapper side of the slam shut body. Install two flat

head screws through the seal retainer and into the slam

shut body using a hex wrench. Make sure the screws are

tightened eliminating the gap between the slam shut body

and the seal retainer. Insure the tops of the screw are

below the surface of the seal retainer.

10. Slide the o-ring onto the flapper shaft. Being careful not to

damage the o-ring install it into the bore in the slam shut

body.

11. Install the o-rings on the bushing. Slide the bushing

onto the shaft and push it into the slam shut body as far

it will go.

CAUTION

Do not damage the sealing bead on the flapper or the

shut-off valve will leak. If the pins stick up above the

flapper they will cut the seal and cause the shut-off

valve to leak.

Assembly of the Shut-off Valve onto the Body and/or

Regulator

Refer to Figure 10 for this operation.

1. Install the body seal in the Flowgrid body.

2. Slide the slam shut valve assembly over the studs and

onto the Flowgrid body.

3. If the slam shut valve is integrated into a Flowgrid

regulator, assemble the Flowgrid regulator according to

the instructions in the Flowgrid IOM manual in the same

orientation it was removed.

4. If the slam shut is not integrated into a Flowgrid regulator

then install the o-ring and cap on top of the shut off valve

assembly.

5. Install and tighten the four nuts. Torque 2” valves to 65

ft-lbs, 3” and 4” valves to 125 ft-lbs.

Installation of the Controller onto the Shut-off Valve.

Refer to Figure 9 for this operation.

NOTE: With the controller removed the maintenance on

the controller now or later with the unit installed.

1. Lubricated the o-rings with the lubricant supplied in the

rebuild kit.

2. Install the o-rings in the proper grooves in the controller

and latch module where it mates with the shut-off valve

body..

3. Being careful to keep the o-rings in the grooves slide the

controller and latch module over the end of the shaft and

bushing onto the slam shut body. Align the bolt holes,

install and tighten the three bolts.

4. Slide the washer, pawl lever, bushing, pawl spring, and

washer on the stud. Install the spring with the bent leg of

the spring between the two legs of the “L” shaped Pawl

Lever.

5. Install and tighten the nut, enough to remove the slack in

the assembly. Be careful not to over tighten and damage

the threads. Using a pair of plyers, lift the bent end of

the spring over the Pawl lever into the position shown in

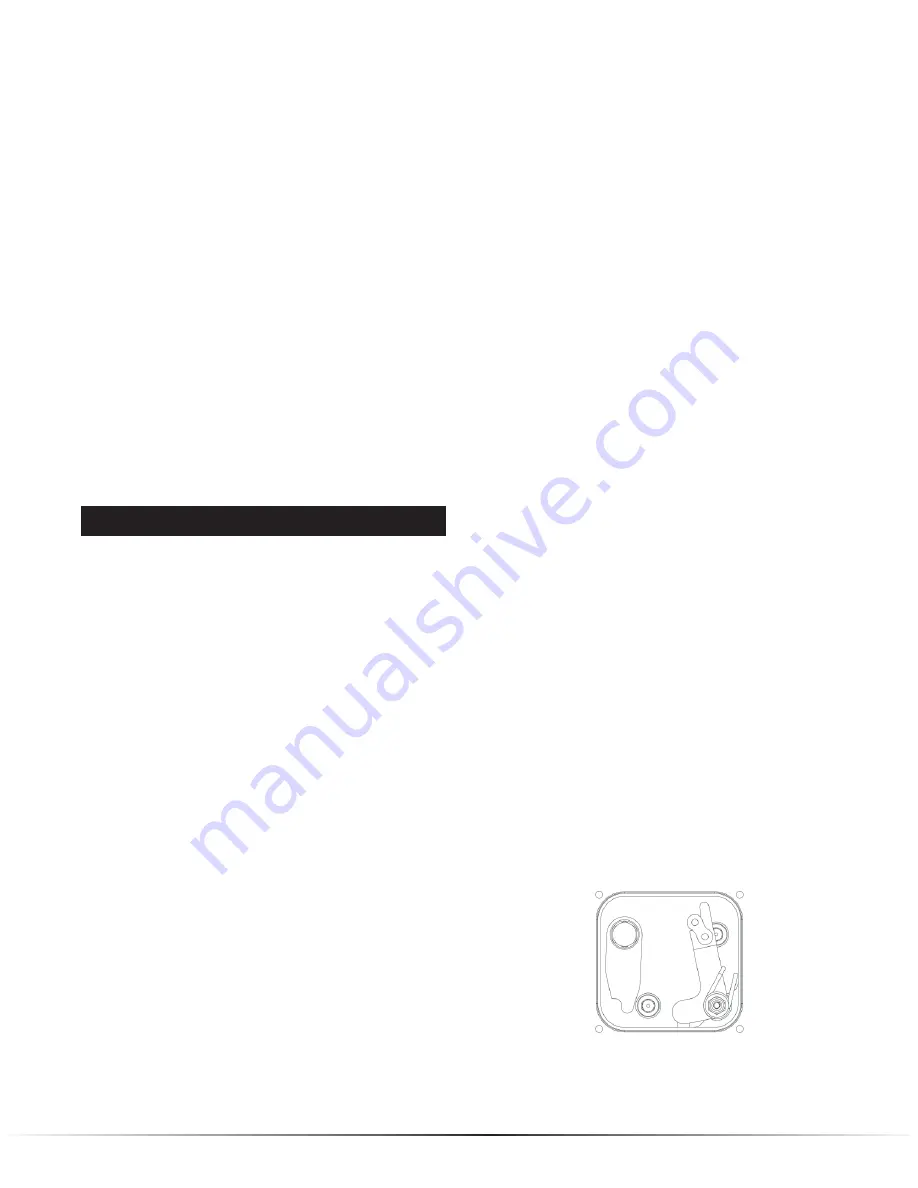

Figure 12.

6. Install the flapper lever so the end of the lever is pointing

down. Install the o-ring on the front reset nut. Install and

tighten the left hand threaded front reset nut on the shaft.

7. Position the cover o-ring on the cover and install the cover

on the front of the lever cavity. Install and tighten the four

cover screws.

Figure 12 - Final spring leg position.