Supplement operating manual for DREHMO i-Matic actuators with integrated

MODBUS fieldbus interface

Wenden, 21.03.12

Page 6 of 18

Prepared by: Ste

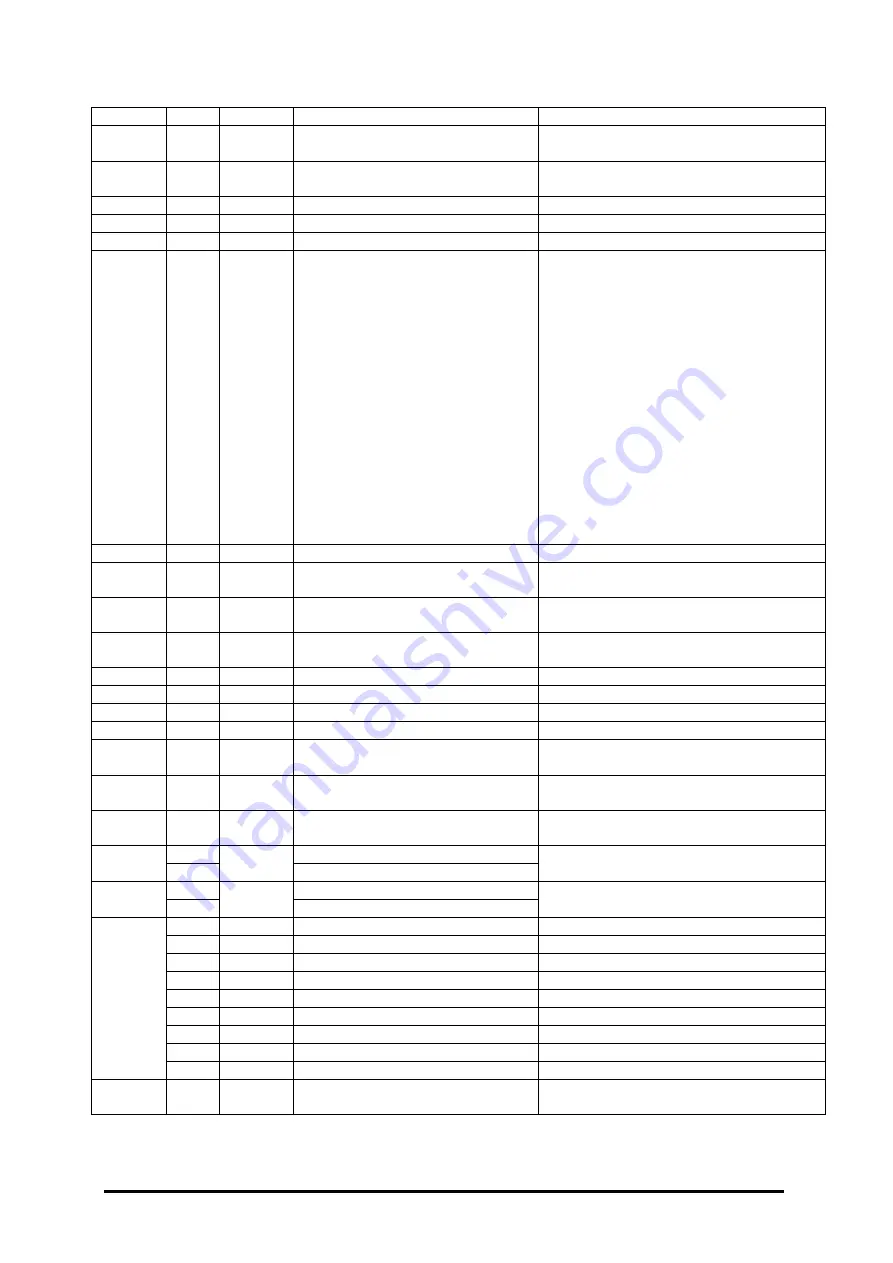

Register Bit

Coil

Signal

Meaning

0x204

0

49

Torque warning OPEN

Torque higher than torque warning level

set

1

50

Torque warning CLOSED

Torque higher than torque warning level

set

2

51

No signal of reference value

If imxx5, message if no reference value

3

52

Hardware fault

Warning message

4

53

Combined sensor defective

Warning message

5

54

system check error

During self-check the electronic unit has

detected an error. The unit then performs

a reset and tries to enter the state fail-

safe. The indication can be cleared by

using the acyclic bit „Reset system test

error“ in slot 1 index 240, or by using the

local reset in system>reset, or by a

power off on cycle. The kind of error

(refer to operating manual of

i-matic

) can

be read out by using the acyclic service

“system test error code” in slot 1 index

195 or the system entry under actual

value diagnosis on the local control

station. This indication is important for

safety related systems, if due to an error

the system needs to be brought to a safe

state.

6

55

Maintenance required

Perm. operating data are exceeded

7

56

Actuator is served

Logged in user is specialist or

manufacturer for service reasons

8

57

Regulating time too long

Regulating time longer than max. running

time

9

58

Max. valve stroke exceeded

Regulating distance longer than stroke of

valves

10

59

Hand wheel operation

Actuators hand wheel is in usage

11

60

Rotation monitor

Set if rotation direction is wrong

12

61

Data exchange channel 1

Data exchange on channel 1 active

13

62

Data exchange channel 2

Data exchange on channel 2 active

14

63

Channel 1 primary

Channel 1 commands are in use due to

highest channel priority

15

64

Channel 2 primary

Channel 2 commands are in use due to

highest channel priority

0x205

0..15

65..80

Torque value

0...1000ppt of the torque value at power

output

0x206

0..7

81..96

Position value low byte

0...1000ppt of analogue input 1

8..15

Position value high byte

0x207

0..7

97..112

Position value low byte

0...1000ppt of analogue input 2

8..15

Position value high byte

0x208

0

113

Process input 1

State of digital input 1

1

114

Process input 2

State of digital input 2

2

115

Process input 3

State of digital input 3

3

116

Process input 4

State of digital input 4

4

117

5

118

6

119

7

120

8..15

121..128

0x209..

0x220

129..512

In order to access the feedback signals, the function codes FC 05 (Force Single Coil) or FC 06 (Preset Single

Register) have to be used. The following tables give telegram examples for these function codes.