11

1. If oil spillage is noted, check oil level,

refer to “Maintenance” section.

NOTE: Jack must be bled before use to

ensure any air is expelled from the

pump unit before use.

2. To bleed jack before use check to see

that the release valve is opened by

turning pump handle anti-clockwise.

(Never more than two full turns

anti-clockwise), pump 5 - 10 full

strokes to purge any air from the

system and evenly distribute the

hydraulic oil.

3. Tighten release valve.

4. Check jack lifts and lowers smoothly

before use.

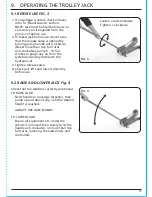

9. OPERATING THE TROLLEY JACK

9.1 BEFORE USE FIG. 3

Check that the saddle is correctly positioned.

TO RAISE LOAD

Twist handle in clockwise direction, then

pump up and down fully, until the desired

height is reached.

ALWAYS USE AXLE STANDS.

TO LOWER LOAD

Ensure all equipment etc. under the

vehicle is removed, then slowly twist the

handle anti-clockwise, no more than two

full turns, lowering the load slowly and

controlled.

9.2 RAISE AND LOWER JACK Fig. 4

FIG. 4

FIG. 3

Loosen = anti-clockwise

Tighten = clockwise

Summary of Contents for TJ3HD/C

Page 15: ...NOTES 15...