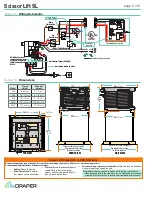

Section 11 -

Electrical Connections

Lift operates on 115V, 60 Hz. current. 14 amps current draw

(2 amps

for lift, 12 amps for Outlet)

Lift ships with internal wiring complete and

control switch

(es)

fully boxed.

Wire to connect lift to switch

(es)

and switch

(es)

to power supply

should be furnished by installer.

Please Note:

Lift must be installed in accordance with

requirements of Local Building Codes, Canadian Electrical Code

(CEC)

, CAN/CSA C22.1 and National Electric Code

(NEC)

, NFPA

70. An appropriate disconnect device shall be provided as part of

building installation.

CAUTION:

All operating switches should be "off" before power

is connected.

Terminal strip for field connections is located inside a junction box

on the end of the unit. Unit ships with internal lift wiring complete to

terminal strip. Use switch to lower lift and remove packing. Remove

temporary wiring and complete permanent wiring to electricity and

to switches. Wire to connect unit to power supply and to switches

should be furnished by installer. Connections should be made

in accordance with wiring diagram. Lift should be operated and

checked prior to installing projector and/or optional ceiling closure.

Section 13 -

Testing Safety Limit Switches

CAUTION:

Lift is equipped with two Safety Limit Switches

(see "Adjustments")

.

This switch may be damaged during shipping or by rough handling on the

job site.

1.

After the Lift has been installed in the ceiling, but before the projector and

closure are attached, the Safety Limit must be tested.

2.

Use a screwdriver or other tool to hold down the Safety Limit Switch. While

holding down Safety Limit Switch, other installer should operate the unit. If

the unit works, Safety Limit Switch is broken and must be replaced.

CAUTION:

Operating the unit without a functioning Safety Limit Switch

could cause the unit's motor to continue operating after the lift is closed,

leading to a failure and the possibility of damage or injury.

Please Note:

As weight is applied to the Lift, the projector plate may shift

slightly. If this occurs, use set screws on bottom of fabric roller brackets to

compensate for shift and level projector plate.

Section 14 -

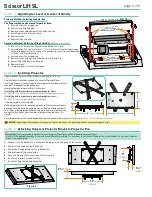

Adjusting Limit Switches

Caution:

The maintenance/service factory limit setting must

not be adjusted to a lower position than the preset factory limit

setting. In addition, Draper does not recommend setting show

position at the maintenance/service position.

PLEASE NOTE:

Changing the fully open or fully closed position will reset the

electronic controls and cause the lift to operate improperly. Please call Draper

before attempting these adjustments.

Adjusting FULLY DOWN position

1.

Limit switches for the Scissor Lift are preset at the

factory. The DOWN limit switch is set for the fully down

(maintenance)

position for the size lift you have ordered.

The limit switch assembly is located inside the lift and

behind the Lifting Cable Drum.

2.

The Down limit switches shown in the drawing are for

setting the "Fully Down" position.

This can be adjusted manually by

loosening or tightening the screw

to increase or reduce the travel.

DOWN

Limit

Switch

ROTATE

TO

ADJUST

DOWN

Section 12 -

Operation

CAUTION:

When operating for the first time, cycle unit down and up several

times to confirm satisfactory operation. Be prepared to cut POWER if

necessary.

• 110-120V SINGLE STATION CONTROL -

3-position UP-OFF-DOWN switch

permits operation to be stopped at any point. Factory adjusted limit switches

automatically stop screen when fully down or fully up.

• 24V CONTROL -

3-button UP-STOP-DOWN switches stop at any point desired

and operate in any sequence. Factory adjusted limit switches automatically

stop screen when fully up or fully down. Installer should incorporate an all-pole

disconnect in fixed wiring available with RF or IR remote.

• KEY OPERATED SWITCHING -

Two key-operated switches optionally

available with this unit:

•

Key-operated power supply switch controls power to screen and switches.

When "off", switches will not operate screen. Key may be removed from

switch in either "on" or "off" position.

•

Three-position key switch permits the screen to be operated directly by key.

Requires screen operator to have a key.

• RS232 / ETHERNET -

Serial communication and network communication

optionally available.

page 7 of 8

Scissor Lift SL