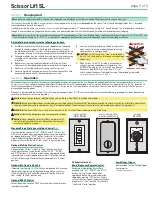

Section 1 -

Hanging Unit

Please note:

If using Environmental Air Space Housing option, see installation instructions included with Environmental Air Space Housing.

The Scissor Lift may be installed in a variety of ways; recessed above the ceiling, or suspended below the ceiling. The lift should be supported by four

3/8

" threaded

mounting rods or bolts with locking nuts.

If ceiling recessed, the entire unit

(including the projector)

should set approximately 1½" above the finished ceiling in its “stored” position. The threaded rods should pass

through the corner mounting flanges and be secured by nuts above and below. The unit should then be guy wired or blocked to prevent swinging.

Please Note:

Scissor Lift must be installed in accordance with the requirements of the Local Building Codes, the Canadian Electrical Code

(CEC)

, CAN/CSA C22.1 and

the National Electric Code

(NEC)

, NFPA 70, as required. An appropriate disconnect device shall be provided as part of the building installation.

All installations should observe the following guidelines:

1.

Installer must ensure that all fasteners and supports are of adequate

strength to securely support Lift and projector. Hardware structure

should be able to hold at least four

(4)

times the combined weight of the

lift, projector, housing, closure, and ceiling material attached to closure.

2.

Fastening methods must be suitable for mounting surface, and securely

anchored so that vibration or abusive pulling on unit will not weaken

installation.

3.

Bottom of unit must be unobstructed after installation. Sufficient

clearance must be allowed below projector or optional ceiling closure.

4.

Do not use unit to support adjacent ceiling, light fixtures, etc.

5.

Do not complete the ceiling below unit until electrical connections have

been completed and unit has been operated successfully.

CAUTION:

BEWARE OF PINCH POINTS!

6.

Use slots on the projector plate and on the closure to

adjust the unit to ensure proper alignment of ceiling

closure relative to ceiling opening.

CAUTION:

DO NOT hang from, "ride," or pull down on

the unit. This could create a failure and cause damage

and/or injury.

7.

When Scissor Lift is NOT installed in environmental

air space housing and optional ceiling closure, the

ALTERNATE wiring for 'UP' limit switch may be used.

Disconnect both BLACK

(BK)

wires from 'UP' limit

switch and quick connect them together using the provided jumper cable

(see Alternate Wiring schematic on page ??)

.

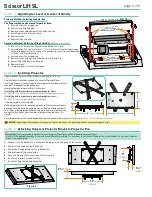

Section 2 -

Operation

Before operating or testing the unit, make sure the packaging has been removed from the unit. Remove the corrugated block from the cardboard sleeve

(bottom-most

packaging material)

, then collapse the sleeve and remove it, along with the rest of the packaging. Next, using the 3 button switch, operate the lift in the "up" direction, so

the lift's control encoder will recognize it's "home" location. Until you do this, the Down function will not work. You must also do this if the Scissor Lift ever loses or is

disconnected from the power.

When unit is first operated, be cautious! If unit fails to operate properly, press “STOP” and recheck electrical connections before proceeding. Cycle unit down and up

several times to confirm satisfactory operation.

Caution:

Do not pull on or touch safety belt when unit is in motion. If belt locks, the cables will unspool.

WARNING:

To prevent operation by unauthorized persons the locking switch cover MUST be installed over the 3-button wall switch for installations where the lift

show position will descend to a height less than 8 feet above the floor. The actuating switch controls shall be located within sight of the projector lift.

WARNING:

To prevent risk of injury, verify that no person is in the vicinity of the device before raising or lowering.

Caution:

Obstructing bottom pan may cause cables to unspool.

Caution:

Do not operate Scissor Lift without a minimum of 15

lbs. of weight attached to the pan. Operating without weight

may cause cables to unspool.

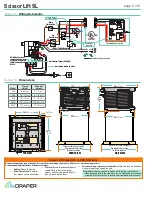

Standard Single Station Low Voltage Control

(Fig. 1)

One three-button switch with “UP”, “DOWN”, and “STOP” buttons.

Lift starts up or down when appropriate button is pressed, and may

be stopped by pressing “STOP” button. Factory set limit switches

stop lift automatically when projector is in “show” position. One

momentary key switch lowers lift from “show” to “service” position.

Optional Multiple Station Control

Optional, moves lift from “stored” to “show” position only. Each

switching station has a three-button switch with “UP”, “DOWN”,

and “OFF” buttons. Lift starts up or down when appropriate button

is pressed, and may be stopped by pressing “OFF” button. Factory

set limit switches stop lift automatically when projector is in “show”

position.

Optional Key Operated Switch

If ordered, the standard Lift LV Switch can be replaced with a second

single station, momentary key-operated three position

(up/off/down)

switch. Multiple Station Control required for this option. Moves lift

from “stored” to “show” position only.

Optional RS232 Control

For Serial communication an R2D7 Serial Communications Interface

is optionally available.

Optional Infrared or

Radio Frequency Remote Control

If ordered, a three-button transmitter is

provided, with “UP”, “DOWN”, and “STOP”

buttons. Unit starts up or down when

appropriate button is pressed, and may be

stopped by pressing “OFF” button. Factory

set limit switches stop unit automatically when

projector is in “show” position. Only controls

"show" and "stored" positions.

Low Voltage Trigger

Input provided for Low Voltage Trigger

from projector

(see diagram on page 4)

.

FRONT

SIDE

BACK

LIFT LV SWITCH

Up & Show

UP

DOWN

OFF

SP-KSM

Service

LIFT LV SWITCH WITH

LOCKING COVERPLATE

LVC-S With

Locking Coverplate

page 3 of 8

Scissor Lift SL