- 14 -

BASIC WOODTURNING

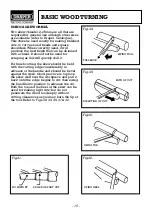

POSITIONING CHISEL AND TOOL REST

FOR DIAMETER SCRAPING

When diameter scraping, the area to the right

of the centre is moving upward (

Fig.34

). If the

chisel is placed in this area it will simply be

carried up and off the tool rest, possibly out

of your hands. So all diameter approach

operations MUST be done at the left of the

centre.

Three different chisel contact points are

shown (

Fig.35

). Note that when the chisel is

positioned above or below the workpiece

centre, the work surface sweeps past the

chisel edge at an angle and will tend to carry

the chisel in one direction along the tool rest.

Only when the chisel contacts the workpiece

centre line does the workpiece pass squarely

under the edge of the chisel. This then is the

position in which it is easiest to hold the

chisel steady. To obtain the position place the

rest approximately 3mm below the centre.

USING THE GOUGE CHISEL

Three gouges 6, 12, 18mm sizes are usually

sufficient for home workshop turning, but

other sizes are available (refer to Draper

Catalogue). A gouge chisel is normally used

for rough circumference turning or turning

raw stock down to a cylinder of workable

size. It is best used for rapid removal of the

workpiece, but will not produce such a

smooth finish, but with practice it can be

used for cutting coves, for shaping long cuts

and is also useful for scraping.

When used for cutting, the gouge is always

held with the convex side down and should

be rolled approximately 30° to 45° in the

direction in which it is being advanced along

the rest, the cutting edge would be a little in

advance of the handle,

Figs. 36

&

37

.

Fig.34.

Fig.35.

Fig.36.

Fig.37.

TOOL REST

TOOL REST

CUTTING

EDGE

ADVANCED

WRONG

CORRECT