12

SECTION V - MAINTENANCE AND STORAGE

IMPORTANT: Knives should be checked for sharpness and the nuts and bolts attaching them to the

flywheel for tightness every 8-10 hours of operation.

If the cutting mechanism strikes any foreign object or if your machine should start making an

unusual noise or is vibrating, stop the engine, disconnect

both

spark plug wires from the spark

plug. Allow the engine to cool before you;

a. Inspect and examine for obvious damage.

b. Check for loose parts, bolts, and nuts.

1. When not in use, your chipper should be stored out of the reach of children. Be sure there are no gasoline

fumes in the storage area. For long periods of storage (over winter), refer to the engine owner’s manual.

2. After every 10 hours of operation, lubricate the chipper side and drive side bearings with multi-purpose lithium

grease. Also, check the bearing collar set screws regularly to be sure they are tight. If they are loose, reset

them with loctite 243 or equivalent, obtainable at any hardware store.

3. You will find information included referring to operation and maintenance of the chipper engine. Look it over

carefully. BE CERTAIN TO SERVICE THE ENGINE BEFORE YOU START IT.

4. When the steel chipping knives (item #8, pg. 19) need replacing or sharpening, refer to the section on removal

and re-installation of chipper knives on pg. 12.

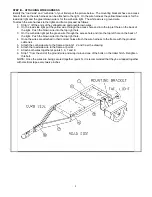

5. Care must be exercised when sharpening the blade to maintain the correct bevel and a straight edge. When

you install a knife, the clearance between knives and wear plate

must be checked. This clearance or gap should be minimum

1/16”, maximum 3/16” (See figure 3). To adjust this clearance,

loosen the three 1/4 inch flathead bolts (item #11, pg. 19) which

are located on the outside of the chipper wear plate (item #12, pg.

19) next to the chipper side plate. Move the wear plate in or out as

necessary and tighten the ¼ inch nuts securely.

6. Note, if the gap between chute plate and knife is excessive, you

will have vibration when chipping and the blade will seem to be

dull.

7. If at any time it becomes necessary to disassemble the chipper for

repairs, the chipping disc (item #3, pg. 19) must be re-installed in

exactly

the same position on the shaft.

Figure 3

BEFORE STARTING ENGINE, ALWAYS CHECK OIL LEVEL!

Summary of Contents for 18.0 HP

Page 2: ...2...

Page 18: ...18 PARTS BREAKDOWN C182 CHP CHIPPER...

Page 20: ...20 PARTS BREAKDOWN 913 0215 CHIPPER BASIC MACHINE...