23

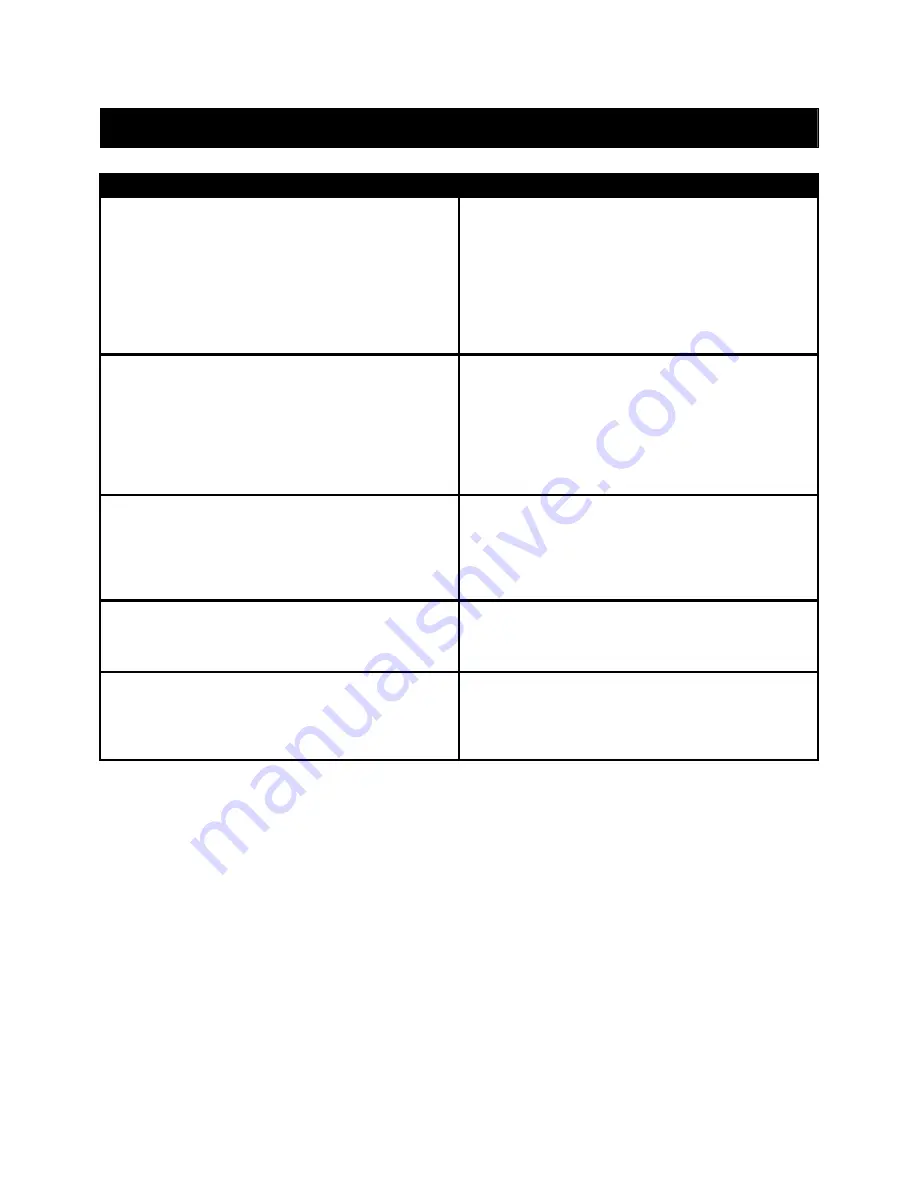

TROUBLESHOOTING

FAILURE

PROBABLE CAUSE

Winch won’t hold load.

a) Excessive

backpressure in the system. Check

the system for restrictions and reduce the

backpressure.

b) Brake discs are worn out. Replace brake

discs.

c) Winch clutch is slipping. Inspect the clutch and

driver for wear and replace worn parts.

Winch will not raise the load it should.

a) Relief valve setting may be too low to allow

proper lifting. Increase relief valve pressure

setting.

(Note: Do not exceed recommended

system pressures)

.

b) Load being lifted may be more than the winch’s

rating. Reduce the load or re-rig to increase

mechanical advantage.

Oil leaks from vent located on the top of the

gearbox.

a) The motor shaft seal may have failed. Replace

this seal and reduce backpressure if that

caused the shaft to fail.

b) Brake piston seals may have failed. Service

the brake section and replace worn parts.

Winch runs too slow

a) Low flow rate. Check the flow rate and

increase if necessary.

b) Hydraulic motor worn out. Replace the motor.

Cable drum won’t free spool

a) Winch not mounted squarely. Check mounting

and confirm that the winch is mounted on a

level surface.

b) Clutch not disengaged. Disengage the clutch.

Summary of Contents for RUFNEK 100

Page 10: ...10 CLUTCH INSPECTION...

Page 27: ...27 VISCOSITY CHART...