When replacing brake cables it is necessary to

adjust the brake shoes before adjusting the parking

brake system. To adjust the shoes, remove the

rubber hole plug in the brake backing plate and

rotate the star adjusting nut until you cannot rotate

the wheel by hand. Then back off the adjustment ten

to twelve (10--12) notches. Note: always rotate

wheel in direction of forward travel only. Replace

hole plug and proceed to next wheel and repeat

procedure.

Adjust parking brakes after all brake shoes have

been adjusted by:

1. Turning knob on brake lever until lever is

perpendicular to bracket when in “OFF” position.

Wheels should turn freely.

2. With lever in “OFF” position, adjust brake cables

until each has approximately the same tension.

Wheels should turn freely.

3. Move lever to “ON” position. Check each wheel

to see that it will not rotate. If all wheels will rotate,

adjust knob on lever until brakes are fully applied. If

one or two wheels will still rotate, adjust the cables

for those wheels and recheck.

4. After brakes are adjusted, move lever to “ON”

position and apply grease to cable strands from

conduit six inches toward lever. This is to prevent dirt

from getting into the conduit.

NOTE:

New cables will stretch and therefore should

be readjusted after the first week of use.

Every six months, apply a multi--purpose grease to

the fittings on the brake actuator.

Electric Brake Adjustment:

Brakes should be adjusted (1) after the first 200

miles of operation when the brake shoes and drums

have “seated”, (2) at 3000 mile intervals, (3) or as

use and performance requires. The brakes should

be adjusted in the following manner:

1. Jack up trailer and secure on adequate capacity

jack stands. Check that the wheel and drum rotate

freely.

2. Remove the adjusting hole cover from the

adjusting slot on the bottom of the brake backing

plate.

3. With a screwdriver or standard adjusting tool,

rotate the starwheel of the adjuster assembly to

expand the brake shoes. Adjust the brake shoes out

until the pressure of the linings against the drum

makes the wheel very difficult to turn.

4. Then rotate the starwheel in the opposite

direction until the wheel turns freely with a slight

lining drag.

5. Replace the adjusting hole cover and lower the

wheel to the ground.

6. Repeat above procedures on all brakes.

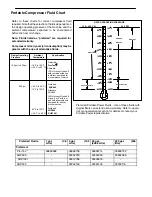

OIL SEPARATOR ELEMENT

The life of the oil separator element is dependent

upon the operating environment (soot, dust, etc.)

and should be replaced every twelve months or

2000 hours. To replace the element proceed as

follows:

* Ensure the tank pressure is zero.

* Disconnect the hose from the scavenge tube.

* Remove scavenge tube from tank cover.

* Disconnect service line from cover.

* Remove (16) cover mounting screws.

* Remove cover, element and inner shell.

* Remove any gasket material left on cover or tank.

* Install new gasket, inner shell and new element.

* Place a straightedge across top of element and

measure from bottom of straightedge to bottom of

element (See Fig. 4.1).