* Bare Airend -- Pertains to major airend parts

(rotors, housings, and bearings).

** Airend Components -- Pertains to auxiliary

attachments to the bare airend (drive coupling,

seals, pumps, valves, tubes, hoses, fittings and filter

housing).

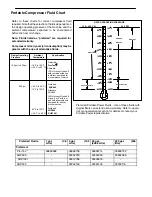

The compressor oil must be replaced every 500

hours of operation or six (6) months, whichever

comes first for models HP600 -- P1600.

Refer to the fluids and lubricants chart for ambient

temperature ranges and specifications, in the

lubrication section of this manual.

The compressor oil must be replaced every 500

hours of operation or six (6) months, whichever

comes first for models P100--P600. The compressor

oil must be replaced every 1000 hours of operation

or six (6) months, whichever comes first for models

HP600--P1600.

Refer to the fluids and lubricants chart for ambient

temperature ranges and specifications in the

lubrication section of this manual.

AIR CLEANER

This unit is equipped with an AIR FILTERS

RESTRICTED lamp on the instrument panel,

covering both the engine and the compressor.

This should be checked daily during operation. If the

lamp glows (red) with the unit operating at full speed,

servicing of the cleaner element is necessary.

Also weekly squeeze the rubber valve (precleaner

dirt dump) on each air cleaner housing to ensure that

they are not clogged. NOTICE: Holes or cracks

downstream of the air cleaner housing will cause the

restriction indicators to be ineffective.

The air filters restricted sensor will automatically

reset after the main power switch is flipped to “OFF.”

To service the air cleaners on all units proceed as

follows:

1.

Loosen outer wing nut and remove with

outer element. Inspect red window on

special inner wing nut to find small dot. If dot

is not visible, remove cotter pin and special

wing nut and inner (safety) element.

2.

Inspect air cleaner housing for any condition

that might cause a leak and correct as

necessary.

3.

Wipe inside of air cleaner housing with a

clean, damp cloth to remove any dirt

accumulation, especially in the area where

the element seals against the housing.

4.

Inspect the primary element by placing a

bright light inside and rotating slowly. If any

holes or tears are found in the paper,

discard this element. If no ruptures are

found, the element can be cleaned by one

of the following procedures.

5.

If a new air filter element is to be used check

it closely for shipping damage. To reset the

signal indicator in the special wing nut, apply

suction to the red window.

6.

Install cleaned or new elements in the

reverse order to the above. Tighten wing

nuts firmly and replace cotter pin.

7.

Inspect to ensure that the end cap seals

tightly 360 degrees around the air cleaner

body.

In the event the element is contaminated with dry

dirt, oil or greasy dirt deposits,and a new element is

not available, cleaning can be accomplished by

washing,

using the air cleaner element

manufacturer’s recommendations.

NOTICE

To prevent damage to the element, never exceed

a maximum air pressure of 100 psi (700 kPa).