WARNING

All DIAGNOSTIC lamps should be off. If not, stop

the machine and investigate.

•

Observe the gauges while the unit warms up for

five (5) to ten (10) minutes or until the coolant

temperature reaches 140

°

F (60

°

C).

•

Push the SERVICE AIR button. The engine

should go to full speed and the discharge pressure

rise to slightly over rated pressure. If there is no air

being consumed, the compressor will unload (intake

should be throttled or closed) and the engine speed

drop to the no load speed.

•

Compressor is now ready to furnish air when the

service valve is opened.

STOPPING

•

Close air service valve(s).

•

Allow the unit to run at “no load” for 3 to 5

minutes to reduce the engine temperatures

•

Flip all toggle switches to “Off”.

NOTICE

Once the engine stops, the automatic blowdown

valve will begin to relieve all pressure from the

receiver--separator system.

CAUTION

Never allow the unit to sit stopped with pressure

in the receiver--separator system.

As a

precaution, open the service valve.

WARNING

Even after pressure is relieved from the

receiver--separator system, any air supply line

from the compressor to a tool or machine could

remain under pressure and cause very serious

personal injury or death. After the compressor

stops, carefully open a valve at any tool or

machine to exhaust the pressure in any line prior

to removal or servicing.

NOTICE

Do NOT wire around or bypass a shutdown

sensor or switch.

All units in this family of machines are protected by

five (5) sensors or switches at the following

locations:

(1) High engine COOLANT temperature in the

engine.

(2) Low engine oil pressure, in the engine.

(3) Low Fuel Level. The light on the control panel

will come on as a warning.

High Discharge AIR Temperature

(4) At the airend outlet.

(5) In the safety valve Tee.

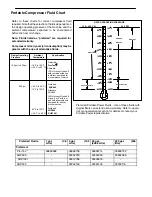

UNITS RATED BELOW 200 PSI (1400 kPa)

These units include an additional low oil pressure

switch in the supply line to the airend bearings.