Operation & Maintenance Manual

The compressor must be towed in a level attitude in order to maintain correct handling,

braking, and lighting functions. This can be achieved by correct selection and adjustment of

the vehicle towing hitch and, on variable height running gear, adjustment of the drawbar.

1. Ensure wheels, tires, and drawbar connectors are in safe operating condition and drawbar

is properly connected before towing.

2. When parking, always use the handbrake and, if necessary, suitable wheel chocks.

Safety Chains/Breakaway Cable And Their Adjustment (Where Fitted).

Ensure breakaway cable is securely coupled to the towed compressor and also to a

substantial anchorage point on the towing vehicle.

Ensure cable length is as short as possible, while still allowing enough slackness for the

towed compressor to articulate without the brake being applied.

Attach safety chains to the towing vehicle at substantial anchorage points of suitable strength.

Ensure effective chain length is as short as possible while still allowing normal articulation of

the towed compressor and proper operation of the breakaway cable.

19

Summary of Contents for P250/HP210WKUB-EX-T2

Page 2: ......

Page 3: ......

Page 6: ...Foreword 5 ...

Page 9: ...8 ...

Page 10: ...Drawbar Information 9 ...

Page 13: ...12 ...

Page 14: ...Safety 13 ...

Page 23: ...Operation Maintenance Manual Safety 22 ...

Page 24: ...Safety Operation Maintenance Manual 23 ...

Page 25: ...Operation Maintenance Manual Safety 24 ...

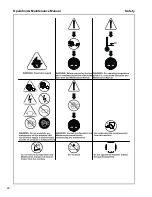

Page 26: ...Safety Operation Maintenance Manual Decal Symbols Graphic Form and Meaning of ISO Symbols 25 ...

Page 27: ...Operation Maintenance Manual Safety 26 ...

Page 28: ...Safety Operation Maintenance Manual 27 ...

Page 29: ...Operation Maintenance Manual Safety 28 ...

Page 30: ...General Data 29 ...

Page 33: ...32 ...

Page 34: ...Operating Instructions 33 ...

Page 43: ...42 ...

Page 44: ...Maintenance 43 ...

Page 53: ...Operation Maintenance Manual Maintenance Maintenance Schedule 52 ...

Page 54: ...Lubrication 53 ...

Page 58: ...Troubleshooting 57 ...

Page 64: ...WARRANTY 63 ...

Page 65: ...64 ...

Page 66: ...65 ...

Page 67: ...66 ...

Page 69: ......

Page 70: ......