MAINTENANCE

34

7/20, P65

SCAVENGE LINE

The scavenge line runs from the combined orifice/drop tube in the

separator tank, to the orifice fitting located in the airend.

Examine the orifice, check valve and hoses at every service or in

the event of oil carryover into the discharge air.

It is good preventative maintenance to check that the scavenge line

and tube are clear of any obstruction each time the compressor

lubricant is changed as any blockage will result in oil carryover into the

discharge air.

COMPRESSOR OIL FILTER

Refer to the

MAINTENANCE CHART

in this section for the

recommended servicing intervals.

Removal

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been completely

relieved of all air pressure.

(Refer to

STOPPING THE UNIT

in the

OPERATING INSTRUCTIONS

section of this manual).

Clean the exterior of the filter housing and remove the

spin

−

on

element by turning it in a counter

−

clockwise direction.

Inspection

Examine the filter element.

CAUTION:

If there is any indication of the formation of varnishes,

shellacs or lacquers on the filter element, it is a warning that the

compressor lubricating and cooling oil has deteriorated and that it

should be changed immediately. Refer to LUBRICATION later in this

section.

Reassembly

Clean the filter gasket contact area and install the new element by

screwing in a clockwise direction until the gasket makes contact with

the filter housing. Tighten a further

1

/

2

to

3

/

4

of a revolution.

CAUTION:

Start the machine (refer to PRIOR TO STARTING and

STARTING THE UNIT in the OPERATING INSTRUCTIONS section

of this manual) and check for leakage before the machine is put back

into service.

COMPRESSOR OIL SEPARATOR ELEMENT

Normally the separator element will not require periodic

maintenance provided that the air and oil filter elements are correctly

maintained.

If, however, the element has to be replaced, then proceed as

follows:

Removal

WARNING: Do not remove the filter(s) without first making sure

that the machine is stopped and the system has been completely

relieved of all air pressure.

(Refer to

STOPPING THE UNIT

in the

OPERATING INSTRUCTIONS

section of this manual).

Disconnect all hoses and tubes from the separator tank cover plate.

Remove the drop

−

tube from the separator tank cover plate and then

remove the cover plate. Remove the separator element.

Inspection

Examine the filter element. Examine all hoses and tubes, and

replace if necessary.

Reassembly

Thoroughly clean the orifice/drop tube and filter gasket contact area

before reassembly. Install the new element.

WARNING

Do not remove the staple from the anti

−

static gasket on the

separator element since it serves to ground any possible static

build

−

up.

Do not use gasket sealant since this will affect electrical

conductance.

Reposition the cover plate, taking care not to damage the gasket,

and replace the cover plate screws tightening in a

criss

−

cross

pattern

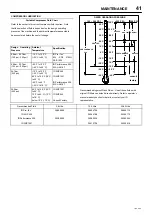

to the recommended torque (refer to the

TORQUE SETTING TABLE

later in this section).

Engage the adaptor in the cover plate with the drop

−

tube integral

with the filter, reconnect all hoses and tubes to the separator tank cover

plate.

Replace the compressor oil (refer to

LUBRICATION

later in this

section).

CAUTION:

Start the machine (refer to PRIOR TO STARTING and

STARTING THE UNIT in the OPERATING INSTRUCTIONS section

of this manual) and check for leakage before the machine is put back

into service.