Downflo Evolution, DFE 2-8 to 5-80

6

X

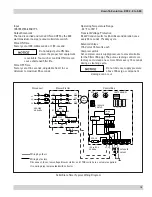

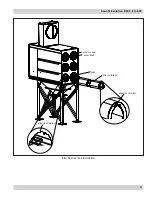

Typical Installation

Typical Installation

1.

Place hopper discharge-side up on ground or other level

surface and attach legs to hopper.

2.

Assemble leg cross braces.

3.

Turn hopper and leg assembly over and lift into position

over anchor bolts.

4.

Level hopper.

5.

Tighten all fasteners securely, including all anchor bolts.

Tighten all hardware

before removing crane.

6.* Apply 1/4-in diameter rope-type sealant to hopper

flange.

7.

Lift collector over leg and hopper assembly and lower

slowly.

8.

Secure with bolts, washers, and nuts supplied.

9.* Apply 1/4-in diameter rope-type sealant around inlet

opening.

10. Lift inlet onto collector. Secure with bolts, washers, and

nuts supplied.

Tighten all hardware before removing

crane.

11. Remove crane.

12. Apply sealant to hopper/cabinet and cabinet/inlet seam.

angle not to

exceed 30°

from vertical

(min 60°

from horizontal)

Do Not lift with

this orientation

Apply sealant

after marriage of

hopper to cabinet

and cabinet to inlet

seam (step 12)

*1/4-in diameter rope-type

sealant (steps 6 and 9)

module flange

3/8-in flat washer

3/8-16 x 1-in bolt

Steps 1-2

Step 10

Steps 3-6

Steps 7-9

*The 1/4-in diameter rope-type sealant supplied with the

collector is temperature sensitive. It may soften and become

difficult to work with at elevated temperatures. Store rope-type

sealant in a cool location before use.

Summary of Contents for DFE 2-4

Page 42: ...A 1 Donaldson Company Inc Appendix A Clean Change Bag In Bag Out Filter and Liner System...

Page 56: ...B 2 Donaldson Company Inc Service Notes Date Service Performed Notes...

Page 57: ...Downflo Evolution DFE 2 8 to 5 80 B 3 Date Service Performed Notes...

Page 58: ...B 4 Donaldson Company Inc Date Service Performed Notes Service Notes...