7

Donaldson Company, Inc.

Standard Equipment

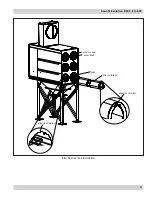

Standard Downflo Evolution collectors consist of

collector module, inlet box, hopper, and legs. The legs

and hopper are assembled first and the collector is

placed in position using a crane or forklift.

Field Assembly

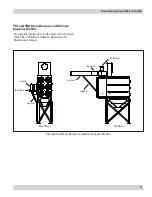

2. Set the hopper on the ground or a flat surface

with the collector connection flange down. The

discharge opening on the hopper base should be

oriented up.

3. Use drift pins to align holes.

4. Reference the Leg Positioning and Leg and Cross

Brace Assembly drawings. Attach the legs to the

hopper gussets using the hardware supplied.

5. Join multiple hoppers together at hopper gussets

using the hardware supplied. Do not tighten

hardware at this time.

6. Turn leg and hopper assembly over and position over

anchor bolts. Secure each leg pad to the foundation

anchor bolts with customer-supplied flat washers

and nuts. Do not tighten hardware at this time.

7. Level hopper.

8. Tighten all hardware securing legs, cross braces,

hopper gussets, and foundation anchor bolts.

Hopper Installation

There are four hopper styles offered for the Downflo

Evolution. A single module hopper spanning a single

collector module with two or three filter columns. A

double module hopper spanning a pair of collector

modules with two filter columns thereby accommodating

four filter columns. A taller, steeper, single module

hopper spanning one collector module with two filter

columns. A single module screw conveyor hopper

spanning one collector module with two filter columns.

All four hopper styles except the screw conveyor hopper

provide a 10-inch square discharge opening. The screw

conveyor hopper provides a single 18-inch discharge

opening.

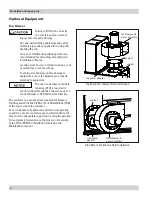

Use proper equipment and adopt

all safety precautions needed for

servicing equipment.

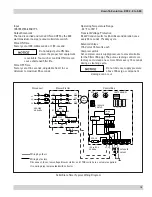

Electrical service or maintenance work must

be performed by a qualified electrician and

comply with all applicable national and local

codes.

Turn power off and lock out all power before

performing service or maintenance work.

Do not install in classified hazardous

atmospheres without an enclosure rated for

the application.

Turn compressed air supply OFF, bleed and

lock out lines before performing service or

maintenance work.

Field assembly of collector may be required due to

truck capacity, crane capacity, or specific customer

requirements. A detailed instruction drawing, shipped

with each collector will provide specific assembly and

lifting instructions.

Tighten all hardware before

removing crane to prevent

personal injury and/or property damage.

Leg Installation

Leg sets for standard collector sizes are shown in the

Rating and Specification Information. Reference Typical

Foundation Anchor and leg assembly drawing shipped

with the collector prior to starting assembly.

1. Prepare the foundation or support framing in the

selected location. Locate and install anchors.

Anchors must comply with local

code requirements and must be

capable of supporting dead, live, wind, seismic,

and other applicable loads.

Anchor sizes shown are provisional, as final

anchor sizing will depend on jobsite load

conditions, collector location, foundation/

framing design variables and local codes.

Consult a qualified engineer for final selection

of suitable anchors.

Summary of Contents for DFE 2-4

Page 42: ...A 1 Donaldson Company Inc Appendix A Clean Change Bag In Bag Out Filter and Liner System...

Page 56: ...B 2 Donaldson Company Inc Service Notes Date Service Performed Notes...

Page 57: ...Downflo Evolution DFE 2 8 to 5 80 B 3 Date Service Performed Notes...

Page 58: ...B 4 Donaldson Company Inc Date Service Performed Notes Service Notes...