Before You Change

That

Cooling Unit

PART I. PROPER DIAGNOSIS

Cooling units are sometimes diagnosed as being

defective when the actual problem is something

else. Cooling units are expensive to replace, so

it is important to make the correct diagnosis. By

using the proper test procedures, you can eliminate

all other possibilities before condemning the

cooling unit.

Any time the cooling unit is a possible suspect,

use the following step-by-step procedure before

replacing it.

A.

1.

2.

3.

4.

PRELIMINARY CHECKS

Check for an ammonia smell around the

cooling unit and inside the refrigerator.

This could indicate a possible refrigerant

leak. Check for any deposits of yellow

powder on the tubing which will sometimes

form around the area of a leak. NOTE: A

yellow deposit in the area of the fill valve

could be due to splashing of refrigerant

during manufacture, and would not indicate

a leak.

Determine if the refrigerator works on one

heat source but not another by testing it in

the alternate modes. Also, ask the customer

if he gets better cooling results from one

energy source than another. If this is true,

it indicates the problem is NOT in the cooling

unit.

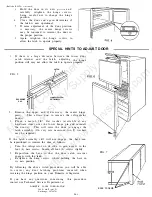

Make sure the refrigerator is level. Sometimes

the vehicle is level but the refrigerator is

not, due to improper installation. Place a

level on the bottom of the freezer compart-

ment and check side-to-side and front-to-back

levels (see FIG. Al). Use a mirror, if

necessary to read the level.

Carefully check door gaskets for proper

seal. A leaking gasket can allow enough

warm air inside the refrigerator to overcome

most of the cooling being produced.

D-9-l 0

REFRlGERATOR

BULLETIN

R61/7A

DEC.

1987

For a simple method to check gaskets, close

the door on a dollar bill, then pull the dollar

bill out. If no resistance is felt, the gasket

is not sealing properly. This should be done

on all four sides of the door.

FIG. Al

CHECK LEVEL

BOTH WAY.

5.

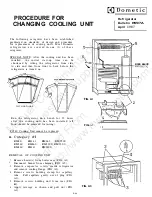

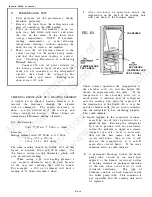

Check the venting system to insure that

ample air flow is provided at the back of

the refrigerator.

A. Check for, and remove, any restrictions

in the vents, such as filters installed by

the customer, bird nests in the roof

vent, or smashed louvers in the wall

vents (see FIG. A2).

B. Make sure the correct roof vent has

been installed. Larger models such as

RM100, 760, 761, 1300, 1303, 2600, 2800,

2802, 3600, 3800, 3802 and 4801, require

a 5” X 24” opening for the roof vent

Smaller models will also use the 5”

24” roof opening. To check this, measure

the actual opening in the roof - DO

NOT measure the roof vent itself. See

FIG. A2.

Manual

Compliments

of

Northwest

RV

Supply

Printed

From

http://www.nwrvsupply.com