(16)

Since the absorption system utilizes no

mechanical pumps or compressors to circulate

the refrigerant within the system, proper leveling

is required to provide correct refrigerant flow in

the gravity-feed system. Without proper leveling,

refrigerant within the cooling coils will collect

and stagnate at certain areas. When this

happens the cooling process will stop.

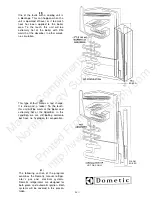

(17)

On the older style cooling units equipped with

square boiler box covers, this condition can

cause permanent cooling unit failure. As we can

see from this drawing, square boiler box

cooling units utilize an exposed siphon pump

tube which will become excessively super-

heated in an out-of-level condition. This can

allow the rust inhibiting agent to chemically

break down and permanently block or restrict

the normal refrigerant flow through the pump.

Shaking, tipping or so called ‘burping the

refrigerator will not loosen or dislodge the

blockage. The only recommended service

procedure is to replace the cooling unit. To

prevent this occurrence, proper leveling is of

utmost importance when the RV is parked for

any length of time.

THREE REQUIREMENTS

FOR PROPER OPERATION

1. Level

REFRIGERATOR IS TO BE LEVEL

(18)

To level these units, the spirit or bubble level

LEVELS

should be placed in the approximate front and

center of the floor of the freezer compartment.

The coach should then be positioned so that at

least 3/4 of the bubble is within the required

mark while the refrigerator is in operation.

REMEMBER: Failure to property level

a square

b

o

ile

r

box

can

r

es

ult

in

a

l

ack

o

f

cooling

or

permanent damage to the coding

unit.

W h e n

the vehicle is moving, leveling is not critical as

the rolling and pitching movement of the RV will

keep the solution in motion, preventing the

solution from accumulating in the piping.

- -

-

D-6-7

Manual

Compliments

of

Northwest

RV

Supply

Printed

From

http://www.nwrvsupply.com