12

SECTION D

SECTION D

SECTION D

SECTION D

SECTION D..... MAINTENANCE & SER

MAINTENANCE & SER

MAINTENANCE & SER

MAINTENANCE & SER

MAINTENANCE & SERVICE

VICE

VICE

VICE

VICE

TIPS FOR THE SERVICE TECHNICIAN

The User should be aware of service that must be done on a regular schedule to keep the refrigerator

The User should be aware of service that must be done on a regular schedule to keep the refrigerator

The User should be aware of service that must be done on a regular schedule to keep the refrigerator

The User should be aware of service that must be done on a regular schedule to keep the refrigerator

The User should be aware of service that must be done on a regular schedule to keep the refrigerator

operating properly. The service should only be performed by a qualified technician.

operating properly. The service should only be performed by a qualified technician.

operating properly. The service should only be performed by a qualified technician.

operating properly. The service should only be performed by a qualified technician.

operating properly. The service should only be performed by a qualified technician.

C. Check the AES control system by connecting/discon-

necting 120 volt AC power, start/stop the engine, etc.

Compare the operation with the operation described in

Section C. Operation Instructions

.

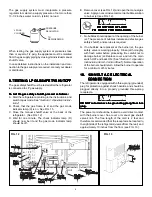

D. The LP gas pressure should be checked and the main

regulator readjusted if pressure is incorrect. The cor-

rect operating pressure is 11 inches of water column.

The correct place to take the LP gas pressure is at the

test port just ahead of the burner jet. (See FIG. 16)

E. Inspect the flue baffle. It should be reasonably clean

and free of soot. Heavy soot formation indicates im-

proper functioning of the burner. The flue and burner

both require cleaning in the following manner:

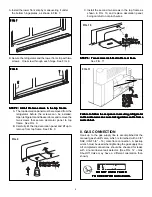

1) Unplug the refrigerator power cord from the 120 volt

AC outlet (see FIG. 13).

2) Disconnect or shut off the 12 volt power to the

refrigerator.

3) Turn manual shutoff valve to OFF. (See FIG's. 12 &

16).

4) Remove cover from the burner housing. (See FIG.

12).

5) Disconnect the wire from the high voltage electrode.

6) Remove the burner mounting screws and remove

the burner assembly.

7) Lift out the wire and spiral baffle. Clean the flue from

the top using a flue brush. Blowing compressed air

into the flue will not properly clan soot and scale out

of the flue tube. Replace spiral baffle and flue cap.

8) Clean burner tube with a brush. Blow out burner with

compressed air.

9) Before removing burner jet, clean burner area of

soot and scale that fell out of flue tube. Remove the

burner jet. Soak the jet in wood alcohol and blow it

out with compressed air. Reinstall and tighten burner

jet.

DO NOT

DO NOT

DO NOT

DO NOT

DO NOT use a wire or pin when cleaning the burner

use a wire or pin when cleaning the burner

use a wire or pin when cleaning the burner

use a wire or pin when cleaning the burner

use a wire or pin when cleaning the burner

jet as damage can occur to the precision opening.

jet as damage can occur to the precision opening.

jet as damage can occur to the precision opening.

jet as damage can occur to the precision opening.

jet as damage can occur to the precision opening.

This can cause damage to the refrigerator or create

This can cause damage to the refrigerator or create

This can cause damage to the refrigerator or create

This can cause damage to the refrigerator or create

This can cause damage to the refrigerator or create

a fire hazard

a fire hazard

a fire hazard

a fire hazard

a fire hazard.

1.

1.

1.

1.

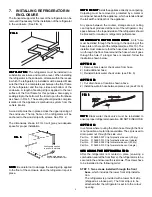

1. REFRIGERATOR REMOVAL

REFRIGERATOR REMOVAL

REFRIGERATOR REMOVAL

REFRIGERATOR REMOVAL

REFRIGERATOR REMOVAL

Before working on the refrigerator, make sure the AC

voltage and DC voltage leads are disconnected. Shut off

the gas supply. Disconnect the gas supply line. Cap the

gas supply line, loosen the screws anchoring the refrigera-

tor to the enclosure and slide the refrigerator out of the

compartment.

Replacement is the reverse of removal. Check all connec-

tions for gas leaks. Refer to

Section A, Item 1 to 12 of

Installation Instructions

.

2.

2.

2.

2.

2. PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

To keep your Dometic refrigerator operating efficiently and

safely, periodic inspection and cleaning of several compo-

nents once or twice a year is recommended.

A. It is important to keep the area at the back of the

refrigerator clean. Check the lower vent, upper vent

and area between these openings for any obstructions

such as bird/insect nests, spider webs, etc. Clean the

coils on the back of the refrigerator. Use a soft bristled

brush to dust off the coils.

It is important to keep the refrigerator area free

It is important to keep the refrigerator area free

It is important to keep the refrigerator area free

It is important to keep the refrigerator area free

It is important to keep the refrigerator area free

from combustible material, gasoline and other flam-

from combustible material, gasoline and other flam-

from combustible material, gasoline and other flam-

from combustible material, gasoline and other flam-

from combustible material, gasoline and other flam-

mable vapors or liquids.

mable vapors or liquids.

mable vapors or liquids.

mable vapors or liquids.

mable vapors or liquids.

NOTE

NOTE

NOTE

NOTE

NOTE: The following maintenance is required once or

twice a year, but should only be done by a qualified

serviceman who is familiar with LP gas systems and

refrigerators.

B. Check all connections in the LP gas system (at the back

of the refrigerator) for gas leaks. The LP gas supply

must be turned on. Apply a noncorrosive bubble solu-

tion to all LP gas connections. The appearance of

bubbles indicates a leak and should be repaired imme-

diately by a QUALIFIED SERVICEMAN WHO IS FA-

MILIAR WITH LP GAS SYSTEMS AND REFRIGERA-

TORS.

DO NOT USE A FLAME

DO NOT USE A FLAME

DO NOT USE A FLAME

DO NOT USE A FLAME

DO NOT USE A FLAME

TO CHECK FOR GAS LEAKS.

TO CHECK FOR GAS LEAKS.

TO CHECK FOR GAS LEAKS.

TO CHECK FOR GAS LEAKS.

TO CHECK FOR GAS LEAKS.