Original Operating Instructions

Framax stripping corner I hydraulic

13

999239002 - 07/2018

Maintenance

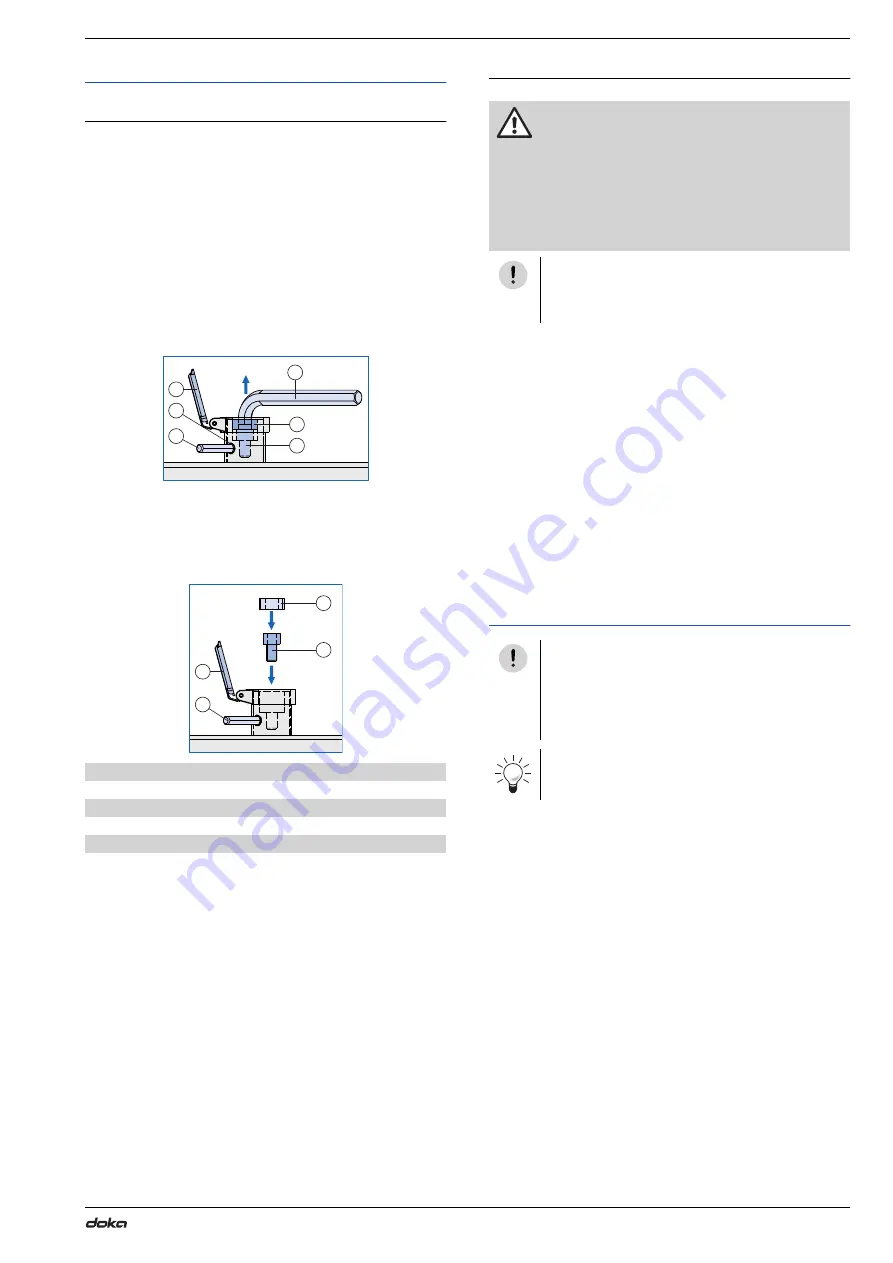

Changing the drive

Note:

The drive hexagon socket (width-across 8 mm) has to

be replaced if it is damaged.

There are 3 spare cylinder screws M10x20 - 10.9 in the

documents container.

➤

Open the blue drive flap.

➤

Insert the bit (width-across 8 mm) into the locking

bore.

➤

Loosen locknut (width-across 12 mm) with hexagon-

socket screw key (width-across 12 mm).

➤

Remove cylinder screw M10x20 - 10.9 and replace it

with a new cylinder screw M10x20 - 10.9.

Width-across, hexagon socket 8 mm

➤

Retighten the locknut (width-across 12 mm).

Changing the oil

➤

Unscrew the plug with a hexagon-socket screw key

(width-across 5 mm).

➤

Lift the unit on to a used-oil drum and drain the oil

into the drum.

➤

Re-seal the plug with Teflon tape, and screw it back

in.

➤

Open the screw at the oil filling opening.

Width-across 17mm

➤

Refill the reservoir with approx. 3

litres of hydraulic

oil (up to the maximum mark). Use 'Shell Tellus S2

V15' hydraulic oil.

➤

Re-seal the oil filling opening.

➤

Dispose of the waste oil and soiled cleaning utensils

correctly. Observe all relevant national laws.

Transport

A

Drive flap

B

Locking bore

C

Bit (width-across 8 mm)

D

Locknut (width-across 12 mm) (painted red

E

Hexagon-socket screw key (width-across 12 mm)

F

Cylinder screw M10x20 - 10.9 (drive hexagon socket (width-

across 8 mm)

F

A

9239-203-01

D

B

E

C

A

C

9239-203-02

F

D

CAUTION

Risk of burns or scalds if an oil change is

attempted while the hydraulic oil is still hot!

➤

If the hydraulic unit has been in operation for

a lengthy period, allow the hydraulic oil to

cool down before changing the oil.

Maximum oil temperature for oil changes:

40°C.

NOTICE

Interval for oil change:

▪

once a year

NOTICE

Do not put the hydraulic unit on its side!

Putting the hydraulic unit on its side causes

damage to the unit and leakage of hydraulic

oil.

The handles or the strap can be used for trans-

porting the Hydraulic unit Framax V4.