20

Maintenance

Do not rely solely on mechanical or hydraulic jacks for support.

Use adequate jack stands or equivalent support.

Motion Control Lever Linkage Adjustment.

1. Adjustment must be made with the drive wheels turning. Raise the

frame and block so that drive wheels rotate freely.

2. Remove the electric circuit of the seat safety switch under the

seat. Install a jumper wire to the end of the harness connector

temporarily.

3. Run the unit at least 5 minutes with the drive levers at full forward

speed to bring hydraulic system oil up to operating temperature.

4. Start engine. Brake must be engaged and motion control levers out

to start engine. Operator does not have to be in the seat because

the jumper wire is being used. Run engine at full throttle.

NOTE: The motion control lever needs to be in neutral position

while making any necessary adjustments. The left lever controls the

left rear drive wheel, while the right lever controls the right rear drive

wheel.

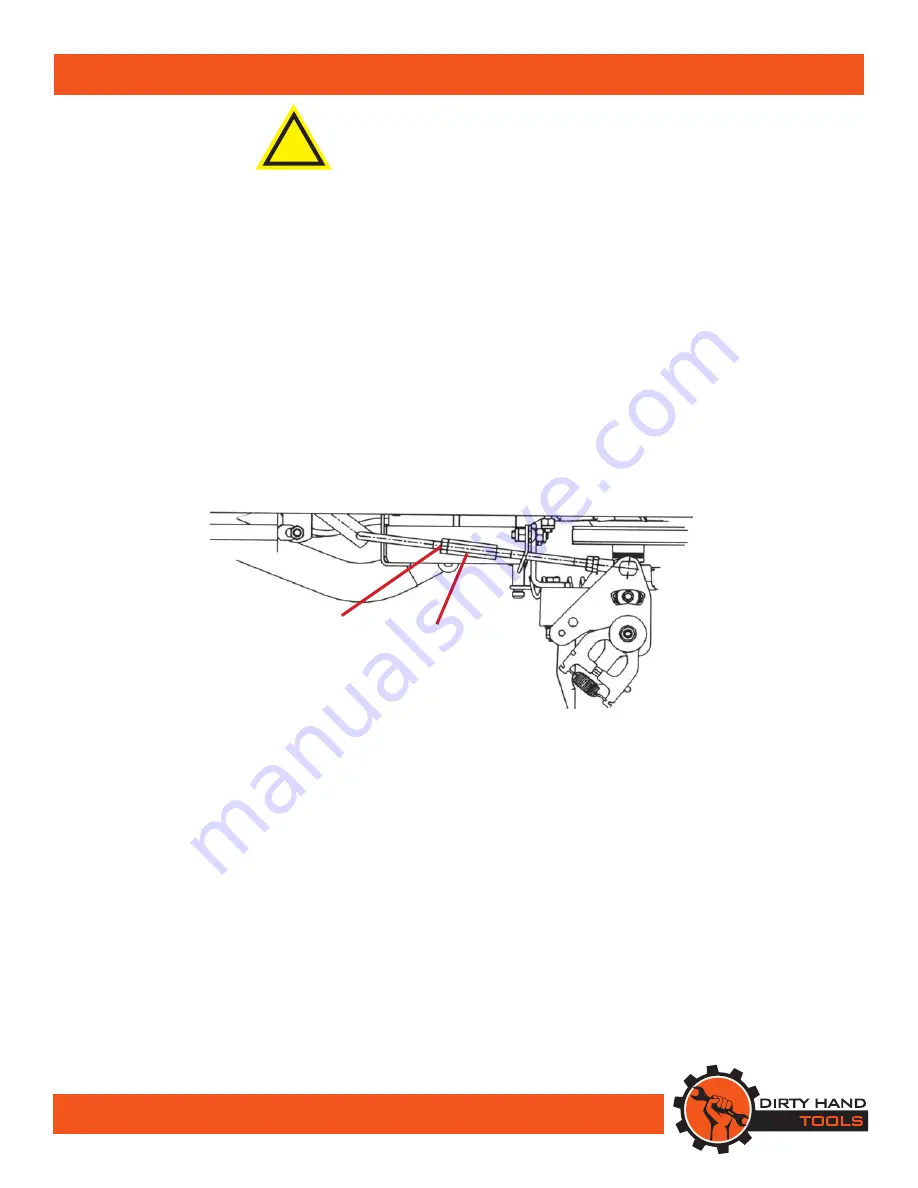

5. Place the left motion control lever to the neutral position. Loosen

the lock nut on the lever. Rotate the turnbuckle in the middle of

the lever to adjust the length of left hydrostatic transaxle in proper

way until the wheel stops. Pull the lever slightly when it’s in the

neutral position. The motion control lever will rebound to the

neutral position by the reaction power of a spring. The wheels will

stop running or turn back slightly. After doing this, tighten the

lock nut (see Figure 9).

6. Repeat method to adjust length of right motion control lever.

7. Plug in the seat switch.

Figure 9

!

WARNING

Turnbuckle

Lock

Nut