7

TIG WELDING WITH “Lift” TYPE STRIKING

4a) Open the gas cylinder and flow regulator.

5a) Put the electrode at the point at which welding is to begin, put

the TIG torch at an angle so that the edge of the gas nozzle

is not on top of the piece to be welded, keeping contact be-

tween the point of the electrode and the piece to be welded

(Fig. D-1).

6a) Press the torch button.

7a) The “Lift” function strikes the arc when the TIG torch electrode

comes into contact with the workpiece and is then removed

(Fig. D-2)

8a) Carry out TIG welding (Fig. D-3).

To end welding:

•

Lift the torch slowly, at a certain point the welding current

decreases, and then stop.

•

The welding power source follows an automatic down slope

along with extinguishing of the arc.

9a) When finished welding remember to shut off the gas cylinder.

TIG WELDING WITH HIGH FREQUENCY STRIKING (HF)

4b) Open the gas cylinder and flow regulator.

5b) Put the electrode at the point at which welding is to begin, put

the TIG torch at an angle so that the edge of the gas nozzle is

not on top of the piece to be welded, keeping a 2-3 mm gap

between the point of the electrode and the piece to be weld-

ed (Fig. E-1).

6b) Press the torch button.

7b) The voltaic arc strikes even without contact between the TIG

torch electrode and the workpiece (Fig. E-2).

8b) To continue welding put the torch back in its normal position

(Fig. E-3).

IMPORTANT: The high frequency switches off automatically af-

ter switching on.

PART TO BE WELDED

The part to be welded must always be connected to ground in or-

der to reduce electromagnetic emission. Much attention must be

afforded so that the ground connection of the part to be welded

does not increase the risk of accident to the user or the risk of dam-

age to other electric equipment. When it is necessary to connect

the part to be welded to ground, you should make a direct con-

nection between the part and the ground shaft. In those countries

in which such a connection is not allowed, connect the part to be

welded to ground using suitable capacitors, in compliance with the

national regulations.

WELDING PARAMETERS

Table 3 shows the currents to use with the respective electrodes

for TIG welding. This input is not absolute but is for your guidance

only; read the electrode manufacturers’ instructions for a specific

choice. The diameter of the electrode to use is directly proportion-

al to the current being used for welding.

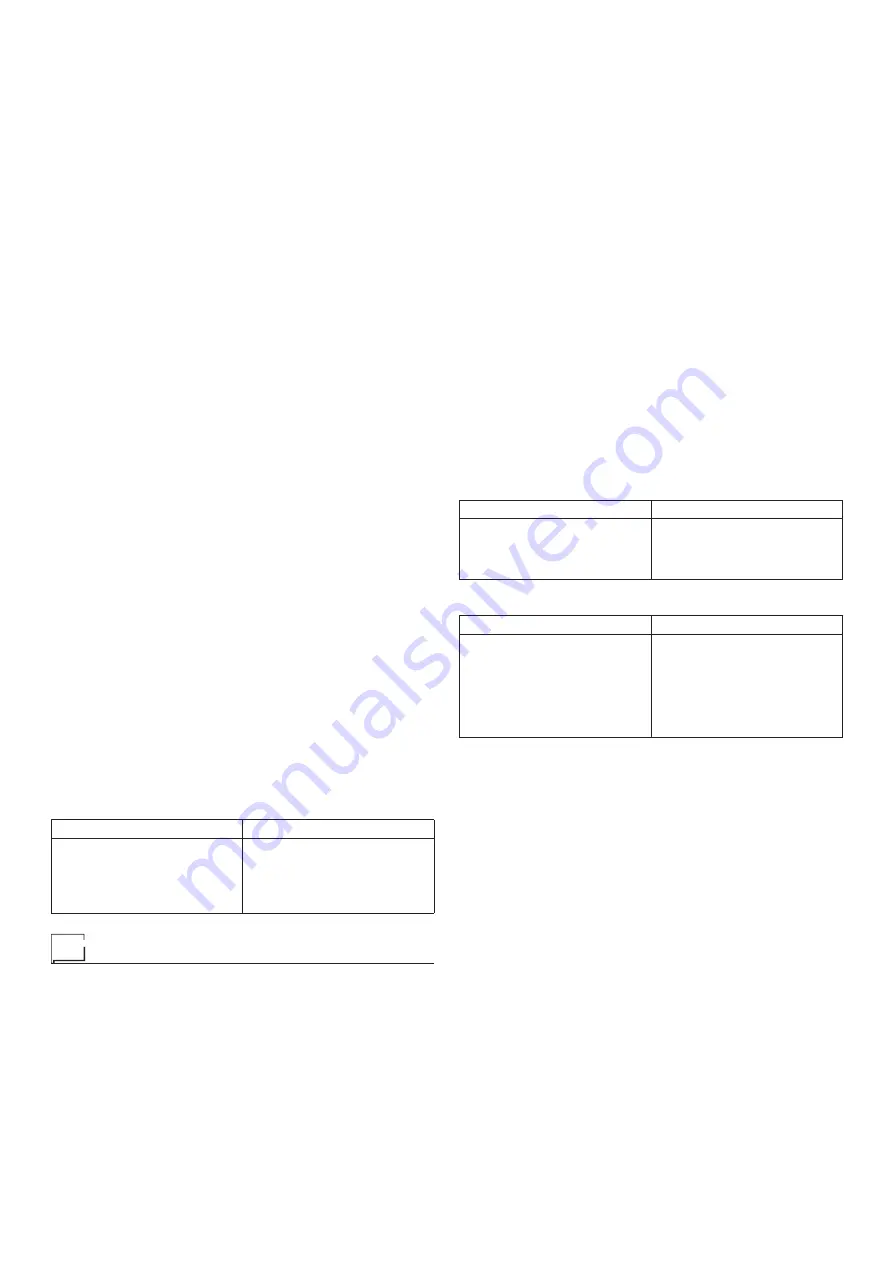

Table 3

Ø ELECTRODE (mm)

CURRENT (A)

1,2

1,6

2,4

3,2

4,0

10 ÷ 80

70 ÷ 150

140 ÷ 250

225 ÷ 400

300 ÷ 500

Electrode welding (MMA)

The welding electrode is used to weld most metals (various types

steel, etc.),for which rutilic and basic electrodes are used.

1) Connecting the welding cables (Fig. F):

Disconnect the welding power source from the mains power

supply and connect the welding cables to the output terminals

(Positive and Negative) of the welding power source, attaching

them to the clamp and ground with the polarity specified for the

type of electrode being used (Fig.F). Always follow the elec-

trode manufacturer’s instructions. The welding cables must be

as short as possible, they must be near to one another, posi-

tioned at or near floor level. Do not touch the electrode clamp

and the ground clamp simultaneously.

2) Switch the welding power source on by moving the power sup-

ply switch to

I

(Pos. 6, Fig. A).

3) Make the adjustments and select the parameters on the con-

trol panel (for further information see the control panel manu-

al).

4) Carry out welding by moving the torch to the workpiece. Strike

the arc (press the electrode quickly against the metal and then

lift it) to melt the electrode, the coating of which forms a protec-

tive residue. Then continue welding by moving the electrode

from left to right, inclining it by about 60° compared with the

metal in relation to the direction of welding.

PART TO BE WELDED

The part to be welded must always be connected to ground in or-

der to reduce electromagnetic emission. Much attention must be

afforded so that the ground connection of the part to be welded

does not increase the risk of accident to the user or the risk of dam-

age to other electric equipment. When it is necessary to connect

the part to be welded to ground, you should make a direct con-

nection between the part and the ground shaft. In those countries

in which such a connection is not allowed, connect the part to be

welded to ground using suitable capacitors, in compliance with the

national regulations.

WELDING PARAMETERS

Table 4 shows some general indications for the choice of elec-

trode, based on the thickness of the parts to be welded. The val-

ues of current to use are shown in table 5 with the respective

electrodes for the welding of common steels and low-grade al-

loys. These data have no absolute value and are indicative data

only. For a precise choice follow the instructions provided by the

electrode manufacturer.

Table 4

WELDING THICKNESS (mm)

Ø ELECTRODE (mm)

1,5 ÷ 3

3 ÷ 5

5 ÷ 12

≥ 12

2

2,5

3,2

4

Table 5

Ø ELECTRODE (mm)

CURRENT (A)

1,6

2

2,5

3,2

4

5

6

30 ÷ 60

40 ÷ 75

60 ÷ 110

95 ÷ 140

140 ÷ 190

190 ÷ 240

220 ÷ 330

The current to be used depends on the welding positions and the

type of joint, and it increases according to the thickness and di-

mensions of the part.

The current intensity to be used for the different types of welding,

within the field of regulation shown in table 5 is:

•

High for plane, frontal plane and vertical upwards welding.

•

Medium for overhead welding.

•

Low for vertical downwards welding and for joining small pre-

heated pieces.

A fairly approximate indication of the average current to use in

the welding of electrodes for ordinary steel is given by the follow-

ing formula:

I = 50 × (Øe - 1)

Where:

I = intensity of the welding current

Øe = electrode diameter

Example:

For electrode diameter 4 mm

I = 50 × (4 - 1) = 50 × 3 = 150A

Summary of Contents for DIX TIG GO 1906.M HF

Page 5: ...5 FIG A ...

Page 10: ...10 Wiring diagram DIX TIG GO 1906 M HF ...

Page 11: ...11 2101WA31 ...

Page 12: ...12 Wiring diagram DIX TIG GO 2506 M HF ...

Page 13: ...13 2101WB24 ...