24

Editing the maximum and minimum

limits for welding parameters

Welding power source in STANDARD (Std) configuration:

During TIG welding with HF ignition, the units allow you to modify

the MINIMUM and MAXIMUM LIMITS for some WELDING

PARAMETERS, thereby providing a more skilled welder and a

more versatile welding power source.

Proceed as follows:

1) Switch on the welding power source holding down the WELD-

ING PARAMETERS SELECTION key (T7).

2) Press the WELDING PARAMETERS SELECTION Key (T7)

a number of times to set the limits for the following welding

parameters:

L10

L16

L15

L12

L11

T7

L11

PRE-GAS duration (maximum limit settable from 1,00

to 2,50 sec)

L12

SLOPE UP duration (maximum limit settable from 5,00

to 10,0 sec)

L10

MINIMUM CURRENT for remote controls - minimum

limit settable:

1906.M HF

2506.M HF

5 ÷ 220 A

5 ÷ 300 A

WARNING: If the minimum limit setting (for the remote control

MINIMUM CURRENT) is greater than or equal to the value for the

PRINCIPAL welding CURRENT I

1

, you will weld at the PRINCI-

PAL welding CURRENT I

1

, irrespective of the setting you have

chosen for the remote control.

L15

SLOPE DOWN duration (maximum limit settable from

8,00 to 15,0 sec)

L16

POST-GAS duration (maximum limit settable from 10,0

to 25,0 sec)

To exit the setting phase, hold the WELDING PARAMETERS

SELECTION key (T7) down for about

1 second

. The values set

are now active and welding can begin.

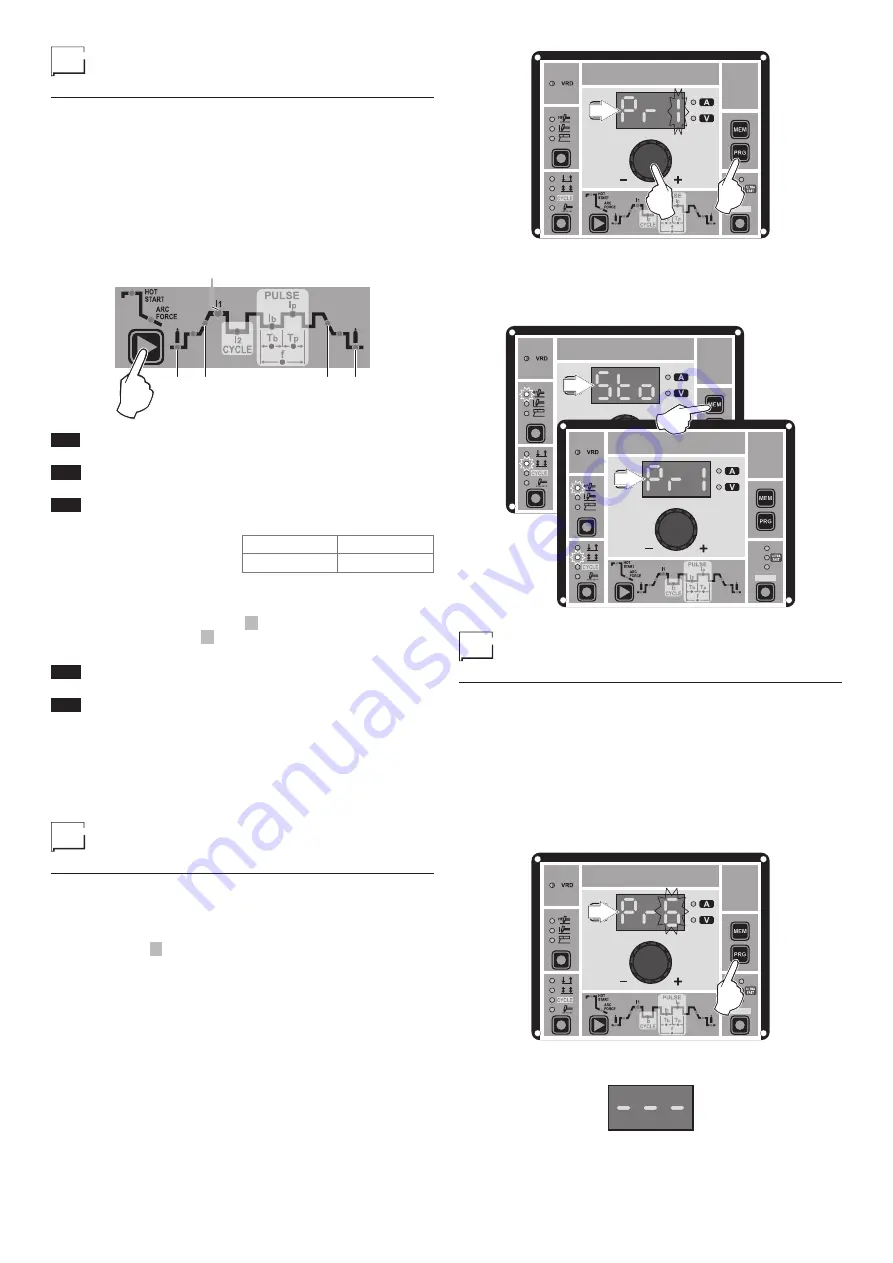

Creating and memorising automatic

welding points

Once you have defined the parameters the operator requires to do

their work properly, you can save them in the memory and create

a WELDING PROGRAM by proceeding as follows.

WARNING: To access the setting saving phase, the PRINCIPAL

CURRENT LED I

1

must be switched on without flashing.

1) Hold the “PRG” PROGRAM Key (T2) down for at least

5

con-

secutive seconds until the DISPLAY (D) reads

Pr

, accom-

panied by a flashing number (e.g. Pr 1).

In order to be able to choose WELDING PROGRAM that is

free, simply rotate the ENCODER knob (E) and look for a

program for which the control panel has all the LEDs for the

various settings switched off.

It is also possible to overwrite a program already saved.

PULSE

SYN

FAST

SLOW

T2

D

E

2) To SAVE the PROGRAM hold the “MEM” SAVE Key (T1) down

until the DISPLAY reads

“Sto”

.

3) The WELDING PROGRAM has now been saved and its num-

ber appears in the DISPLAY (D) along with the other settings

saved (corresponding LEDs on without flashing).

PULSE

SYN

FAST

SLOW

PULSE

SYN

FAST

SLOW

D

T1

D

PROGRAMMED and/or

MANUAL welding

PROGRAMMED WELDING

When the WELDING PROGRAM has been saved, the operator

can weld using only pre-set values as they cannot edit any type

of parameter/function. To edit, switch to MANUAL welding mode.

MANUAL WELDING

To go back to set/edit the parameters selected or to create a new

program, proceed as follows:

1) Hold the “PRG” PROGRAM Key (T2) down (about

3

sec-

onds) until the DISPLAY (D) shows the number of the program

selected flashing (e.g.

Pr6

).

PULSE

SYN

FAST

SLOW

T2

D

2) Turn the ENCODER Key (E) anticlockwise until the DISPLAY

(D) shows 3 dashes.

3) Press and release the “PRG” PROGRAM key (T2) and the

welding power source goes back to the initial operation con-

dition.

Summary of Contents for DIX TIG GO 1906.M HF

Page 5: ...5 FIG A ...

Page 10: ...10 Wiring diagram DIX TIG GO 1906 M HF ...

Page 11: ...11 2101WA31 ...

Page 12: ...12 Wiring diagram DIX TIG GO 2506 M HF ...

Page 13: ...13 2101WB24 ...