Troubleshooting

D3655-US Rev E

EZ400 User’s Manual

25

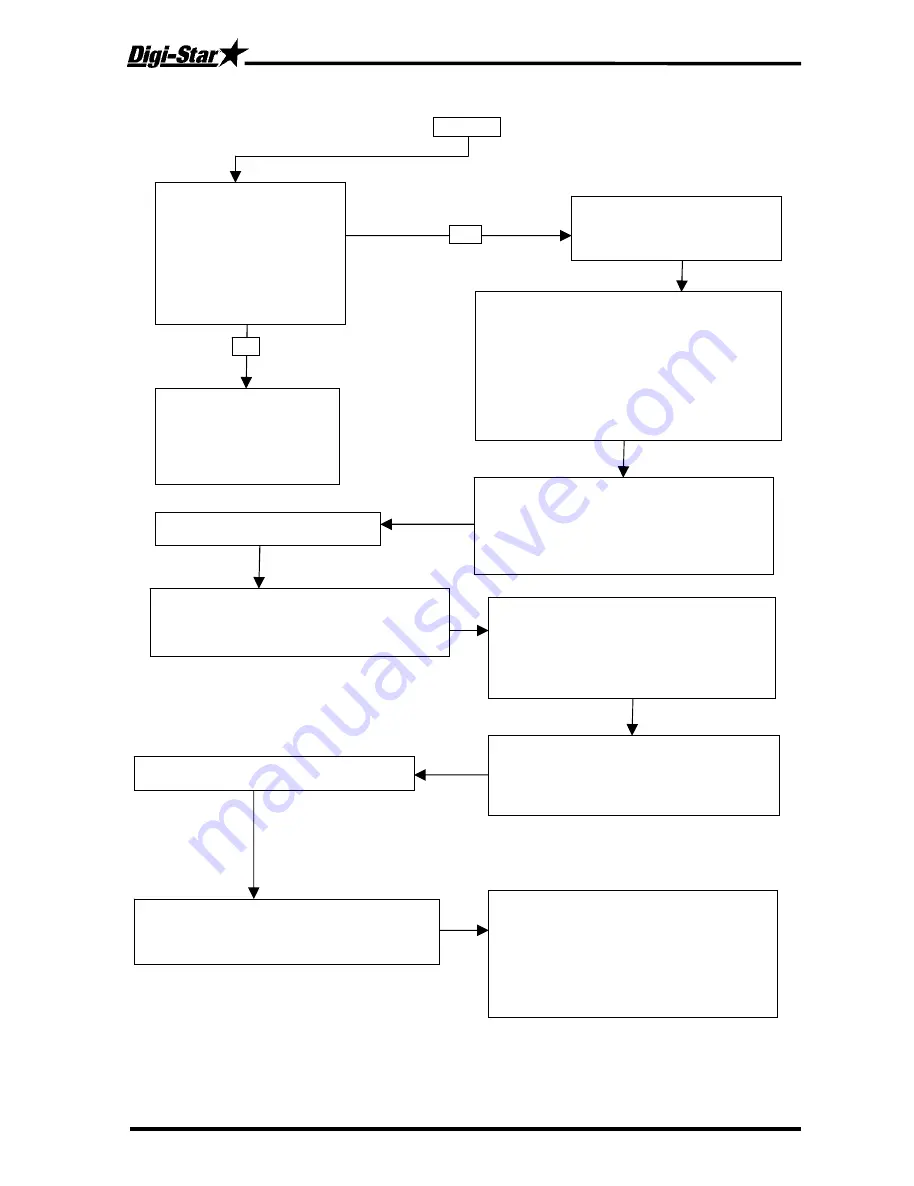

FLOW CHART

Continued

1. Disconnect all the Load Cell

wires from the terminal blocks

inside the J-Box (leave the

Indicator on while connecting

and disconnecting the wires, it

will not damage Load Cells or

Indicator if wires are shorted

during this step). Is reading on

Indicator stable?

2. Zero balance the Indicator.

(Press “NET/GROSS” then

“ZERO”). Indicator should display

“0”.

YES

Replace J-Box

(be aware of electrical

interference that might affect

your scale such as: mobile

phones, CB radios, radio

towers, electric motors, etc.).

NO

Note:

Hook up the Load Cells to the J-Box one at

a time (only one Load Cell connected at a time).

This will get a reading for each Load Cell. While

performing this test, watch for any other

symptoms such as erratic/unstable display.

Indicator flashing “±RANGE”, negative reading,

etc. If the Indicator reading should ever appear

abnormal with any Load Cell connected then it is

probably bad.

4. Record the Indicator reading with

the Load Cell connected.

3. Connect one Load Cell back into one of the

terminals in the J-Box. (The reading you get for

each Load Cell is dependent on the size and type

of each Load Cell and how much weight is over

each Load Cell. In general, the number should be

positive and stable.)

5. Stand or hang your weight over the connected

Load Cell. Record how much the weight

increased with your weight over the Load Cell. (A

scale with only one Load Cell will weigh heavy.)

Note:

If the scale responded to your weight,

that’s verification on the J-Box is OK. If the

scale did not respond, either that Load Cell is

bad or the J-Box is bad. Try the other Load

Cells. If the Indicator still shows no response,

the J-Box is bad. (Replace J-Box)

6. Disconnect the first Load Cell and reconnect

a second one. Record the Indicator reading.

Stand or hang your weight over the connected

Load Cell. Record how much the weight

increased.

7. Repeat step 6 for the remaining Load Cells.

Remember to record your readings.

Do not expect the Load Cells to give the same

reading. It is common for Load Cells to have

readings that vary by hundreds, even thousands.

Especially when one is carrying more weight.

8. Bad Load Cells will have a reading that is

either unstable, makes the indicator flash

“±RANGE” or is more than three times greater

or less than the average of the others. Also the

readings of your weight over each Load Cell

should be similar. (Probably 4 times your actual

weight). Any differences could be an indication

of a bad Load Cell or a structural problem.

All manuals and user guides at all-guides.com