Element Series Manual

Page | 3

Feed Water Requirements

1.

Plumbing feedin

g the element must be at least ¾” in diameter.

2.

Filtered water must be used on the membrane

. The element has a 5 micron filter to remove

particles to drastically extend the life of the membrane. Changing these filters every month is

recommended to extend the life of the membrane. Follow instructions on page 10 to change

filters.

30-0021-XX

Replacement 5 Micron Filter

30-0122-XX

Alternate Replacement 5 Micron Filter

3.

Soft Water is recommended.

Excessive water hardness or iron concentrations may form scale

over the membrane and cause clogging. This will drastically reduce the useful life of the

membrane. Installing a water softener before each system to reduce hardness and iron is

recommended.

4.

Anti-Scalent recommended.

Slightly soluble contaminants like calcium sulfate, silica, or colloidal

clay will cause clogging. A continuous injection of an anti-scalent should be used if these

contaminants are present.

Recommended Specifications:

Total Dissolved Solids

< 2000 ppm

Hardness

< 17 ppm

Iron

< 0.1 ppm

Manganese

< 0.1 ppm

Silica

< 10 ppm

Hydrogen Sulfide

< 0.0 ppm

Organics

< 2 ppm TOC

Turbidity

< 0.1 NTU

Feed SDI

< 3.0

pH

3

–

10

Free Chlorine

0.1 ppm

Temperature

40-95°F

Inlet Pressure

20

–

80 psi

Membrane Operating Parameters:

Membrane

Thin Film Composite

Typical Operating Pressure

150-200 psig

Max Pressure:

400 psig

pH Range Continuous

3

–

10

pH Range, Cleaning

1

–

12

Max Pressure Drop

10 psig per membrane Max Calcium Hardness < 0.0 LSI

Nominal Rejection

98%

Max Temperature

113°F

Summary of Contents for Element ELE-1600-LT

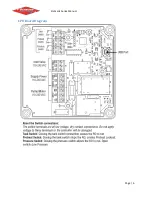

Page 4: ...Element Series Manual Page 4 Control A diagram of the Element controller is shown below...

Page 5: ...Element Series Manual Page 5 Inner Control Box...

Page 6: ...Element Series Manual Page 6 CPU Board Diagram...

Page 7: ...Element Series Manual Page 7 DIP Switch Settings...

Page 8: ...Element Series Manual Page 8 Programming Guide...

Page 9: ...Element Series Manual Page 9 Programming Interface...