15

English

OPERATION

Instructions for Use

WARNING:

Always observe the safety instructions and

applicable regulations.

WARNING:

To reduce the risk of serious personal

injury, turn tool off and disconnect battery pack

before making any adjustments or removing/

installing attachments or accessories.

An accidental

start‑up can cause injury.

Attaching an AirLock

™

Compatible Dust

Extractor (Fig. K3)

WARNING:

When using dust extraction, empty vacuum

before work begins and often during work. Use care in

disposing of dust. Dust can be hazardous to health if

inhaled, ingested or in contact with the skin. Materials in

fine dust can be explosive.

Your tool is compatible with the

D

e

WALT

AirLock™ connection

system. The AirLock™ allows for a fast, secure connection

between the AirLock™ connector

21

and the straight

adapter

16

.

1. Remove the battery.

2. Ensure the collar on the AirLock™ connector is in the

unlock position. (Refer to Figure K3.) Align notches

22

on

collar and AirLock™ connector as shown for unlock and

lock positions.

3. Push the AirLock™ connector onto the adapter

connector point.

4. Rotate the collar to the locked position.

nOTE:

The ball bearings inside collar lock into slot and

secure the connection.The power tool is now securely

connected to the dust extractor.

nOTE:

The sleeve of the dust extraction port can be

removed if damaged and replaced by the user. The sleeve is

available as an optional accessory and can be replaced using

a screwdriver.

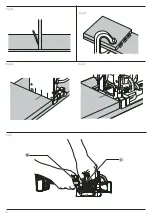

Dust Extractor

1. Insert the appropriate adapter

16

or

17

into the dust

extraction outlet

5

.

2. Connect the dust extractor hose to the adapter.

Dustbag

1. Insert the straight adapter

16

into the dust extraction

outlet

5

.

2. Attach the dustbag

15

to the adapter.

3. Whenever possible, connect a dust extraction device

designed in accordance with the relevant regulations

regarding dust emission.

Dust Extraction (Fig. J1, J2)

Using the appropriate adapter, you can connect either a

dustbag or a dust extractor.

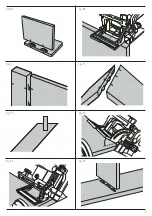

Replacing the Blade (Fig. H, I, J)

WARNING:

• Make sure that the teeth of the cutter point in

counterclockwise direction as shown (Fig. I).

• After replacing the blade, always check the cutting

depth and adjust if necessary.

• Do not use blades or larger or smaller diameter than

recommended. For the proper blade rating refer to the

technical data.

• Use only blades specified in this manual complying

with EN847‑1.

1. Loosen the four T20 Torx headed screws

15

from the base

plate and take off the cover.

2. Depress the spindle lock

10

and remove the flange by

turning it counterclockwise.

3. Replace the blade making sure the teeth of the cutter point

in a counterclockwise direction.

4. Tighten the flange securely by turning it clockwise while

keeping the spindle lock depressed.

5. Mount the cover plate and tighten the hex screws.

Anti‑Slipping Pins (Fig. G)

The anti‑slipping pins

7

help to reduce the tendency of the

biscuit jointer to slide to the left when cutting. When working

on visible parts of the workpiece, you may want to retract them

in order to avoid scratching.

1. To retract the pins, rotate them slightly clockwise using a

flat screwdriver.

2. To use the pins again, rotate them slightly counterclockwise.

only with a new blade and by backing out the fine adjustment

screw (refer to

Plunge Depth Fine Adjustment

).

• Turn the depth adjusting knob

8

into the required position,

aligning the appropriate number with the red arrow on

the tool.

Plunge Depth Fine Adjustment (Fig. F)

The fine adjustment is used to eliminate possible tolerances in

the size of the biscuit slots.

1. Raise the fence

6

to its uppermost position as

described above.

2. Insert the T20 Torx key as shown and adjust the plunge

depth as required by turning the screw

23

(turn clockwise

to decrease the plunge depth). Each full turn causes a

change in depth of 1 mm.

3. Check the setting by making a trial cut in a piece of

scrap wood.

Proper Hand Position (Fig. D2)

WARNING:

To reduce the risk of serious personal injury,

ALWAYS

use proper hand position as shown.

WARNING:

To reduce the risk of serious personal

injury,

ALWAYS

hold securely in anticipation of a

sudden reaction.

Summary of Contents for XR DCW682P2

Page 1: ...DCW692 ...

Page 3: ...1 Fig A 3 4 5 8 7 11 1 6 9 12 13 2 Fig B 12 14 12 13 XXXX XX XX 20 10 13 ...

Page 4: ...2 6 9 4 Fig C Fig D1 Fig D2 Fig E Fig F Fig G Fig H Fig I 1 11 8 6 2 15 7 23 ...

Page 6: ...4 5 7 5 cm 15 25 cm 15 25 cm Fig N3 Fig N4 Fig O Fig P1 Fig P2 Fig Q1 Fig Q2 Fig Q3 ...

Page 7: ...5 Fig R1 Fig R2 Fig S Fig T1 Fig T4 Fig U1 Fig T2 Fig T3 ...

Page 8: ...6 Fig U2 Fig U3 Fig U4 Fig U5 Fig V 3 18 ...

Page 50: ...48 Українська ...

Page 51: ...49 Українська ...

Page 52: ...530917 03 RUS UA 05 22 ...